One of our more frequent correspondents writes with advice for anyone designing equipment or tooling for a particular machining project:

1. Before starting to design a new instrument for any technical function involving some level of detail, a tool designer must first acquaint himself with a drawing of this detail -- and all the technological operations of this detail, as well as the cutting tools and measuring instruments for these operations. This study will save the designer from many possible mistakes in the course of the project.

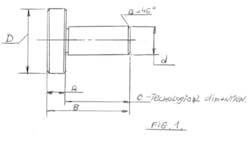

2. Dimensions A design and B — design dimensions are used for as function (See Figure 1.)

For example: a designer is given dimensions A and B to proceed from work detail in the unit. But, for the technological operation of a turning tool, the designer must give side C = B-A, with C as a technological dimension.

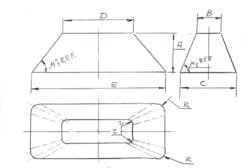

3. Sometimes we need to machine ribs on the detail as a truncated pyramid to a radius. The best way (see Figure 2) is to machine these ribs to radiuses on the CNC (programmable machine tool.)

About the Author

Mark Grizotsky

Owner

Mark Grizotsky, owner of MLG Tool Design in Willowdale, Ontario, has been a major contributor and influencer to machinists everywhere with his insights to machine design and set-up, tooling design and selection, and advice for preparation and processes.