Jet engine builder Pratt & Whitney opened its first manufacturing operation in Singapore, a 180,000-sq.ft. plant where it will produce fan blades and other critical parts for the PurePower® Geared Turbofan™ (GTF) engine family. The plant is operated by a subsidiary, P&W NGPF Manufacturing Co. Singapore Pte. Ltd.

The new plant is adjacent to Pratt & Whitney Component Solutions Pte. Ltd. operation that opened in 2014, which has state-of-the-art engine repair capabilities.

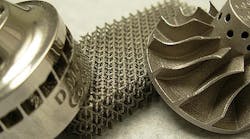

Also, the new plant is only the second Pratt & Whitney plant producing hybrid metallic blades, a very lightweight material that achieves higher aerodynamic efficiency levels than any other material in comparable use, including composite blades of the same size class, P&W noted.

The PurePower GTF is a series of jet engines designed with a gear system separating the engine fan from the low-pressure compressor and turbine, so that each module operates at optimal speed. This means that the fan can rotate more slowly as the low-pressure compressor and turbine operate at a high speed, increasing engine efficiency and reducing fuel consumption, emissions, and noise. According to Pratt & Whitney, that increased efficiency translates to fewer engine stages and parts, which reduces the engines’ weight and maintenance costs.

P&W, a United Technologies Corporation business unit, has about 7,000 orders and commitments (including options) for PurePower engines, from more than 70 customers in over 30 countries. As such, the Singapore operation will be important in the effort to support new demand and service and replacement requirements for GTF engine components by customers in the Asia-pacific region, and worldwide.

"With the opening of this brand new state-of-the-art manufacturing facility to produce our innovative hybrid metallic fan blades and critical turbine rotating components, we are creating much needed manufacturing capacity and capability for our PurePower engine family,” commented said Danny Di Perna, senior vice president, Operations. “Over the past few years, we have invested more than $1 billion globally to create and modernize our manufacturing infrastructure. These investments feature advanced manufacturing equipment, tools, and special processes which play an integral role as we increase production volumes."