The lure of additive manufacturing is strong for operators, suppliers, and designers of manufacturing technology systems – but finding the right approach and applications for the various technologies (3D printing, laser sintering, etc.) emerging as AM has shown how firmly established the current manufacturing processes are, in practice and in concept. Recent months have seen the introduction of several coordinated machining and additive manufacturing concepts: it’s a process likely to have many further developments.

But, a notable step in this development has been accomplished now that Mazak Corporation has introduced its Integrex i-400AM (additive manufacturing) hybrid multi-tasking machine. It’s described as “a fusion of additive technology and Mazak’s most advanced multi-tasking capabilities,” and the developer predicted this machine will reduce part-cycle times significantly as it offers shops a route to “done-in-one” production.

Integrex i-400AM is a turnkey installation. For manufacturers, it will be an alternative to standard routines in terms for part design and machining. And, according to Mazak, it is particularly well suited to small-lot production of difficult-to-cut materials, such as aerospace alloys, high-hardness materials used in energy production tools and components, and high-precision, specialty alloy designs common in medical device manufacturing.

“With the additive capability,” the developer stated, “manufacturers can easily generate/clad near-net-shape component features then quickly complete them with high-precision finish machining operations, as well as laser-mark parts, if needed.”

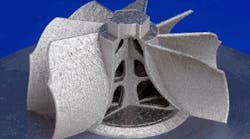

In operation, the Integrex i-400AM takes the laser sintering approach to additive manufacturing. A fiber-laser heat source melts metal powder; cladding heads (i.e., nozzles) deposit the molten material in successive layer defined by a CAD model, each of which solidifies to establish the desired shape.

In addition, the system can join different types of metals to each other, which is advantages for repairing existing worn or damaged components efficiently, such as aerospace turbine blades.

Cladding heads store in the Integrex i-400AM’s tool magazine, and the standard automatic tool changer loads them into the machine’s milling turret.

Mazak offers two cladding head types: high speed or high accuracy. Users select the appropriate head according to their process, and the metal powder to be used.

As for the multi-tasking machine aspect of the Integrex i-400AM design, the system is capable of full five-axis milling to process prismatic parts from solid billets or castings (chucked or bar fed); round parts; highly contoured parts; and parts with features built using additive technology — all these with ease and efficiency.

The machine provides -30/+210 degree B-axis movement in its milling spindle, full C-axis contouring with its turning spindle, and an NC tailstock that is fully programmable.