Los Angeles-based Brush Research Manufacturing is known for inventing the Flex-Hone Tool, now a global brand. This year, the ISO 9001:2008-certified supplier is marking 55 years of surface finishing innovations, and unveiling new products, strengthening supply chains — and helping manufacturers save time and money.

“Keep an open mind,” company founder Steve Rands said, “… experiment. Nothing improves until someone stops and questions an accepted assumption.” BRM continues to uphold Rands’ vision by offering innovations like a new generation of Flex-Hones and other specialty abrasive brushes.

The Birth of the Flexible Hone

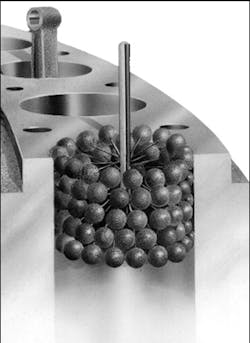

BRM’s signature product, the Flex-Hone, remains the standard for all finishing tools. With a stiff metal stem and flexible nylon abrasive filaments, it removes cut, torn, or folded metal while leaving the base metal undisturbed.

Versatile and easy-to-use, the flexible hone performs edge blending, plateau honing, polishing and chamfer operations, and it can be used with manual or automated production equipment, or even a handheld electric drill.

During the company’s early years, the Flex-Hone was popular mainly in the automotive market. By deglazing the walls of engine cylinders, for example, users extended the service life of diesel engines while reducing oil consumption and lowering emissions.

However, listening to an expanding range of customers, Brush Research began supplying surface finishing solutions to many other industries. Now, the Flex-Hone tool is sold through a global network of distributors for surface finishing of everything from big diesel engines to small brass tubes in musical instruments, as well as honing the barrels and chambers of firearms and chamfering holes in critical parts used in jet engines.

BRM surface finishing products also help customers in industries such as aluminum extrusion, fluid and power, hydraulics, oil and gas, and earth moving equipment. “All of those developments came from listening carefully to the marketplace,” said Jonathan Borden, BRM’s national accounts manager. “That means working directly with customers to provide customized solutions to their application requirements.”

For example, recently Sikorsky Aircraft asked BRM for a tool to remove scale from a carburized bearing surface. The helicopter manufacturer initially attempted to solve the problem by using carbide reamers and diamond laps, but these tools didn’t work well with 9310-alloy steel.

Then, Sikorsky tried BRM’s Diamond Flex-Hone, which uses a diamond abrasive. The BRM tool worked so well that Sikorsky immediately placed a rush order for these high-quality flexible honing tools.

Six Pillars of Success

But the company is much more than its flagship product and other abrasive technologies. Building on the success of the past 55 years, BRM instituted a new focus for its “six pillars of success,” to include value, education, partner support, quality, character, and innovation. These characteristics are more than words; for BRM they are a commitment to providing added value to products that might be viewed as commodity items.

“Within those six pillars are attributes that really set our organization apart and will allow us to continue with our success,” according Jonathan Borden, who has been with the firm for over 10 years and is BRM’s national accounts manager. Borden’s understanding of the company’s product lines and internal business practices is derived from his experience with its customization program, inventory and shipping, marketing, and technical services.

Solving Tough Challenges for Customers

According to Borden, the first pillar – value – represents BRM’s focus on providing added value to distributors and buyers. By offering flexible shipping options along with high-quality products and creative solutions, the company proving that it values long-term relationships.

Stock outs aren’t an option for manufacturers that need industrial brushes to keep their production lines moving. BRM understands the stakes.

“If a brush supplier can’t deliver on-time and on short-demand, it’s the brush distributor who takes the blame,” explained Heather Jones, BRM’s director of marketing. “That’s not fair to the distributor. BRM keeps 98% of catalog items in stock and offers flexible shipping options. This lets distributors reduce inventory-carrying costs and invest their capital in other business opportunities.”

To support its global distributor network, Brush Research offers same-day or next-day shipping.

For the customer, Brush Research provides custom power brush and twisted-in-wire solutions in as little as 24-48 pieces, and the Flex-Hone Tool can be provided in single-piece custom solutions. This ensures that those customers receive the maximum value for their application.

BRM can deliver large quantities of custom brush tools on tight production schedules too, as Sikorsky Aircraft learned after it tried the Diamond Flex-Hone. “Because our facilities are consolidated within a single Los Angeles location, we can coordinate orders with efficiency and offer a quick turnaround,” Grant Fowlie, BRM customer service manager said.

Filling the Sikorksy order was a challenge, but BRM adjusted production schedules and worked overtime to get the job done.

Resources and Relationships

BRM also excels at education, including offering a full electronic library of resource guides that include case studies, high-resolution photography, and video content.

In addition, the supplier scans communication channels for surface finishing needs, including monitoring social media and sharing ideas via Facebook, YouTube, Twitter, and LinkedIn. BRM also posts regular blog entries and press releases, and is planning a mobile application to aid customers with product selection.

At BRM’s website, manufacturers have easy access to free technical books, case studies, and safety and engineering guides. There’s even a downloadable Tech Lab Request Form for specialized applications. After reviewing all of a customer’s specifications, BRM may suggest a standard brush tool or offer to design a custom brush.

The Brush Research site provides instructional videos, with titles like How to Use a Flex-Hone, How to Automate Deburring, and Surface Finishing with NamPower Abrasive Brushes, and How To Use the Flex-Hone for Firearms, a BRM gun tool that’s trusted by gun manufacturers like Beretta, Colt, and Smith & Wesson.

Although much of this material is designed to assist manufacturers and end-users, it is also a critical component of the company’s “partner support” pillar. BRM partners receive access to all of these high-quality materials, along with field support, high-resolution photography, and on-going training and education.

Manufacturing and Quality Improvements

Over the years, one of the biggest changes for BRM has been manufacturing processes, many of which are proprietary. For almost 50 years, when the first Flex-Hone tools were made by hand, the company has continued to invest heavily in automation and quality control systems to improve its manufacturing accuracy and efficiency.

“With advanced technologies and quality management systems you can really control the manufacturing process and that is where many of our advancements have taken place: smaller hones, tighter tolerances, and continuously improved product quality,” Borden explained.

In addition to delivering an array of Flex-Hone models and sizes, BRM offers engineering assistance. At its surface-finishing laboratory in Los Angeles the firm analyzes customer parts that require finishing, then selects and tests the tools that will provide the best solution according to customer operating parameters.

The results include everything from a customized brush with a tapered configuration, or even a stepped-tapered shape of a certain length and honing material.

“Whatever the parameters, we’ll design a brush tool to meet the specific application in the most affordable manner,” said Borden.

The Flex-Hone itself has evolved into new product offerings. In 2012, BRM introduced the Diamond Flex-Hone, which uses diamond crystals laminated to the ends of its flexible filaments. The product is achieves exceptionally smooth surface finishing of cylindrical parts composed of hard materials, such as ceramics, carbide, and hardened tool steel.

Introducing Disc Brushes

Today, BRM is building on a 55-year history of surface finishing success by introducing the NamPower family of disc brushes.

These abrasive nylon brushes contain a combination of ceramic and silicon carbide filaments that deliver maximum burr removal rates and ideal surface finish in a single operation. The abrasive filaments work like flexible files, conforming to part contours, wiping, and filing across part edges and surfaces.

The disc brushes are designed with a new tool holder that allows coolant to flow through its center for better lubricant dispersion. This permits the brush to run at greater cut depths while reducing heat generation to eliminate filament smearing, improve surface finish, and promote longer tool life.

By automating deburring operations with NamPower technology, parts manufacturers can reduce labor costs and speed high-volume parts finishing. Industries that will benefit include aerospace, automotive, industrial, medical and robotics applications.

“Innovation will always remain an important ‘pillar’ to us,” Borden said. “We are continually developing specialty abrasives that are tailored to specific applications to help optimize those applications.”

For more information, visit Brush Research Manufacturing online, or email [email protected]