Chemical 'Machining' of Precise Parts

Edited by Jim Benes, associate editor

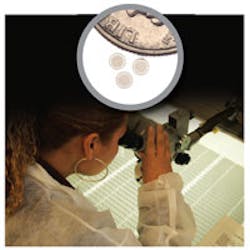

The photochemical machining process, also called photoetching, is effective for producing parts with complex geometries or with many holes where stamping, punching, laser or wire EDM might leave burrs and mechanical or thermal distortion.

Photo-etching fits in a spectrum of metal fabricating techniques that includes stamping, die blanking, punching, laser and water-jet cutting and wire EDM. Its particular advantages include the ability to process very thin materials, to 0.0005-in. thick; the ability to produce complex geometries, including fine meshes, screens and grids; the ability to hold dimensional tolerances to ±10 percent of the metal thickness; and the ability to quickly, and relatively inexpensively, produce quantities from a few to thousands. And, photo-etching does not impart any thermal stress or mechanical deformation in the metal.

The process uses inexpensive and rapidly produced tooling that can accommodate a family of part designs or multiple iterations of a design to accelerate the development process. Photo-etched parts can be produced from metal strips from 0.001-in. to 0.050-in. thick in as little as two or three days. Part sizes range from 0.100 in. with features as small as 0.004 in., to parts as large as 24 in. by 60 in.

> Tolerances and feature sizes

Locational tolerances of features produced by photo-etching are generally within 0.001 in. of drawing nominal. Dimensional tolerances in etching are a function of material thickness and of sheet size. The general rule-ofthumb is that the more generous the tolerances, the larger the sheet size and the lower the part cost.

The tightest tolerance range that can be achieved is ±10 percent of the material thickness for gauges smaller than 0.010 in. For gauges from 0.010 in. to 0.020 in., the range is ±0.0015 in. to ±0.0025 in. From 0.021 in. to 0.035 in., the most economical tolerance is ±0.005 in. Over 0.035 in., the dimensional tolerance band will approximate ± 20 percent of the material thickness.

The smallest hole or minor slot dimension must be at least 110 percent of the material thickness up to 0.020-in. thick, and 120 percent for metals over 0.020-in. thick. The thinnest land area between holes or slots must be at least equal to the material thickness. Minimum dimensions for both inside and outside radii are equal to the material thickness.

> Applications

Photo-etching is useful when time, tooling, part complexity, or material gauge are not well suited to more conventional processes. The process, convenient for “ganging” different parts on a single tool, is also helpful when there are multiple parts (of the same alloy and gauge) in development, or when there are a number of iterations of a design to be tested.

The ability to handle complex geometries or parts with lots of holes provides a distinct advantage over laser cutting, wire EDM, and even CNC punching, both in terms of cycle time and setup time. The ability to do partial-depth etching can eliminate subsequent coining or engraving operations, too. The etching process delivers clean parts and avoids problems of carbon, iron, or cutting lubricant contamination.