Federal-Mogul Corp. is commercializing a new method for machining bushingless steel pistons destined for heavy-duty diesel engines. The powertrain parts manufacturer claims its High Precision Electro-Erosion Machining (HPEEM) process — a variation of electro-chemical machining — will help engine manufacturers produce components that will help them to achieve strict global emissions standards, improve fuel economy, and prolong component life, without compromising engine performance.

Steel pistons are a $200-million global market. Federal-Mogul estimates that approximately 30 percent of today's steel pistons have bushings in the pinhole. But, it projects that from 2012 onward, all heavy-duty diesel engines being will be "bushingless" due to the higher load demands and cost considerations. One of the design objectives for engine manufacturers aiming to hit global targets for lower CO2 emissions is “higher peak cylinder pressure.” Higher PCP requires the size and shape of each component (e.g. steel pistons) to meet tolerances within a few microns. Achieving this high level of precision demands innovative solutions that will not compromise production cost or restrict product reliability.

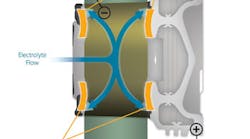

A cross-sectional diagram shows the HPEEM process, with the electrode positioned in the pinhole of a Monosteel piston. The electrolyte flow path and profiled surface are highlighted in orange.

Electro-chemical machining is a "reverse electro-plating" process: rather than adding a layer of metal to a surface, it erodes away a layer.

HPEEM process is very highly controlled electro-erosion method that removes an exact amount of material, precisely shaping the piston pinhole, and thus improving the load transfer capability and reliability of the piston. Having been developed at Federal-Mogul's advanced manufacturing technology development facility in Ann Arbor, Mich., HPEEM is in commercial operation at the company’s piston plant in Puebla, Mexico.

At Puebla, HPEEM produces Monosteel® pistons by machining very precise, accurate, and profiled pinholes that allow the piston to be assembled to a connecting rod without a bushing. The result is a pinhole form machined to extraordinarily tight tolerances, ensuring a design that is affordable and reliable for the OEM. Importantly, it means that the piston can achieve increased cylinder pressure while maintaining robust performance and durability — which lowers engine emissions.

Producing these components by a traditional method would involve a machining center that would be expensive to design, install, and operate, because it would have to be capable of moving a cutting tool precisely through the pinhole, to profile it to the required shape.

HPEEM uses a non-contacting, specially shaped electrode that is positioned precisely in the pinhole. With proper control of the voltage and electrolyte, the electrode uses electro-chemical machining to erode the steel surface of the piston pinhole.

For the Monosteel pinholes, HPEEM has the electrolyte flow between the electrodes and the pinhole surface. Controlled voltage is applied between the part and electrode to erode the material from the pinhole surface. The electrolyte flow washes away the removed material as it exits the piston cavity. With proper control, a profile is machined in the pinhole to a tolerance of a few microns.

"The simplicity of the process is astonishing,” Rainer Jueckstock stated. He is senior vice president of Federa-Mogul’s Powertrain Energy unit. “By using essentially saltwater as an electrolyte and electrical fields as the machining agents, we've developed a method (HPEEM) to machine a piston pinhole so exact and error-free that it surpasses any conventional machining quality-to-cost metric.”

Dr. William Zdeblick, R&D director, advanced manufacturing explained: "Bushingless Monosteel pistons require a steel-on-steel pin joint design. Analysis and testing demonstrated that for this design to work, a high-precision profile needed to be put onto the piston pinhole to properly distribute the load. The profile needed to be uniformly concave and precise to a few microns. Any variation from target runs the significant risk of high stress concentration and potential piston failure.

“However,” Zdeblick continued, “bushingless steel pistons machined conventionally would cost more because of the very high precision requirements on the pinhole profile. The HPEEM process allowed Federal-Mogul to remove the bushing and to provide our customers with pistons that meet their durability requirements — without the added high cost of conventional machining."