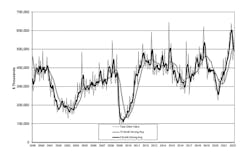

New orders for machine tools rose to $552.3 million during March, up +15.2% from February, and closing Q1 2022 with the highest order total – $1.47 billion – for any comparable period since 1998. The March result is +20.4% higher than the March 2021 figure, and puts the current year-to-date order volume at $1.47 billion, +26.5% ahead of the January-March 2021 total.

The data is supplied by AMT – the Assn. for Manufacturing Technology through its monthly U.S. Manufacturing Technology Orders report. The USMTO report compiles nationwide and regional data of new orders for metal-cutting and metal-forming and -fabricating machinery. USMTO totals – presented in actual dollar values – serve as a forward-looking indicator of overall manufacturing activity, as machine shops and other manufacturers make capital investments in preparation for demand expected in the weeks and months ahead.“The first quarter of 2022 has been extremely impressive for manufacturing technology orders,” stated Pat McGibbon, AMT’s chief knowledge officer. “Previous forecasts had predicted a strong beginning to 2022 and a soft summer, which would rebound by IMTS in September, as summer orders are often delayed in anticipation of new products being exhibited at IMTS.

“However, inflation, the war, and saber-rattling in the east are creating a level of uncertainty and risk that businesses must consider,” McGibbon detailed. “Despite these challenges, we see the manufacturing sector continuing to invest in additional capacity.”

The U.S. regional results showed metal-cutting equipment orders were strongest in the South Central (+39.1%) and Northeast (+31.8%), and still solid in the West (+24.2%) and Southeast (15.1%.) The North Central-West (+13.1%) and North Central-East (+11.4%) also reported positive activity.

AMT noted that USMTO’s Q1 2022 growth coincided with the first negative growth in GDP since 2020 – an early indicator of a manufacturing recession. “To have one of the best quarters in manufacturing technology orders and then find out GDP was contracting over the same time almost defies logic,” McGibbon commented. “However, there have been many instances over the past several months where orders have been up, despite some headwind that would have been a major issue for the industry prior to COVID.”

McGibbon said the shift in purchasing momentum from the industrial to the commercial sector may not be sustained. “Supply-side issues continue to conceal the true potential of consumer demand for manufactured goods, where expenditures have been slipping the past few months,” he said. “While these issues result in shortages for industries that manufacture final consumer goods, manufacturers of components farther from the consumer are amassing backlogs.”

He continued: “Assuming demand for the final good persists despite growing delivery times and rising prices, these growing backlogs for components could fuel demand for manufacturing technology well into the summer months.”