Delcam Plc (www.delcam.com) offers a variety of computer-aided machining software packages that allow users to focus exactly on the processes they use in their shops, and liberally adapt the software to ensure they suit a shop’s specific needs.

Although each of the Delcam products is a unique, stand-alone package, there are some overlapping areas and parts of programs that are interchanged between them.

Delcam incorporates its 5-axis algorithms from its PowerMill program in its FeatureCAM package, for example. Both PowerMill and FeatureCAM now can meet the range of needs from 2-axis to 5-axis machining, but they are meant to be used by machinists who have different skill and experience levels and who work on parts that present dissimilar demands.

By offering a broad range of software options, Delcam provides its customers with what is needed today, and a compatible upgrade path to meet needs as they arise in the future.

So Delcam’s answer to the two questions, “Will the software easily do what I need it to do?” and, “Can it meet future needs?” is “Yes” no matter what those needs might be.

If the need is for a robust power toolkit, PowerMill can supply it. If the need is for a less complex, more automated toolpath and code generation, FeatureCAM is the product of choice. Because Delcam is working to provide a single uniform interface across its full product line, users of one package will be able to quickly adapt to using any of the other products should the need arise.

Delcam’s inspection and 3D CAD modeling software offer users a choice of staying with one vendor for all of their software needs from design and prototyping through machining and assembly.

As to how quick and easy it is to learn, the current interface and functionality of FeatureCAM make it so easy to generate toolpaths from a 3D model that even a magazine editor could learn to do it in less than one hour.

Learning to be efficient in PowerMill would take longer.

Delcam sells its products through distributors, so the quality of training and support depends as much on the quality of the local distributor as it does on the training and support offered by Delcam. Recognizing that training and support are critical to the continued success, Delcam focuses a lot of its energy in making sure that customers get the support they need and want regardless of how that support is delivered.

One of the problems encountered in doing this analysis is that every Delcam customer interviewed had nothing but rave reviews praising Delcam’s software and support. The Delcam users interviewed included those referred by the company but also others who were found by other means. The comments of 11 users is not conclusive, but when they are unanimous in having nothing but good things to say about the software and the company, it is an indication that users have a high satisfaction level with the software, the support, the training and the company that provides it.

Delcam currently has more than 20,000 customers worldwide. That puts the company in the middle of the pack of CAM vendors identified in the April issue of American Machinist. The company is financially stable and said it reinvests more than 11 percent of its annual, net revenues in research and development in addition to its acquisition activities.

In the last 10 years, mergers and acquisitions in the software industry occasionally have left end users high and dry with no support for the software packages they invested in. More than one viable CAM package ended up disappearing from the marketplace because the company that developed it was merged into a part of a larger business.

Exclusive interviews with Delcam’s top management make it obvious that they are keeping the company focused on continuing to build it into a worldclass software developer and not just on quarterly earnings statements. This focus is an indication that Delcam will be around 10 years from now as a continually evolving software developer.

“We’re in this business for the long haul,” said Clive Martell, Delcam’s operations director. “We’re committed to growing the business organically and through selected acquisitions when it’s appropriate.” Martell is part of the next generation of top management being developed by Delcam’s board to insure continuity and growth well into the future.

Delcam offers a unique selling proposition to shop owners and managers. Unlike other software developers who offer one CAM package, Delcam’s array of CAM packages gives buyers a greater chance of finding the one package, or collection of packages, that fits for their needs.

If the shop has experienced programmers who want to control all aspects of the machining, PowerMill fits that need. On the other hand, if the CNC programmers in a shop have limited experience, FeatureMill can be used to automate and simplify their jobs.

In larger shops, both packages could be used at the same time, and shop managers will have the knowledge that the programs are compatible. In addition, Delcam gives shops the ability to incorporate compatible inspection and reverse engineering capabilities through its PowerInspect and CadCopy packages. All machine shops use some form of CAD software in their workflow. Some shops use standalone packages, while others use proprietary software.

Delcam’s PowerShape and Crispin CAD software packages offer an alternative to those packages, but are not as full-featured a replacement. Nor does it have all of the extensions that the more commonly used CAD packages have, but those extensions usually are meant to be used in the product design phase rather than in the manufacturing phase and may not be needed or used by most machine shops.

It is possible to do a side-by-side, feature-by-feature analysis of any one of the Delcam products with any one of the other CAM software packages being offered, and that is something a prospective buyer should do before committing to any package.

But to limit the decision making process to only considering the results of a side-by-side comparison of just one of Delcam’s products ignores the full potential of what the company offers.

It is not just one software package, it is a suite of software tools that are designed to provide whatever a user needs in a robust package that has a consistent, user-friendly interface. That is something that only a few of the other software developers offer.

CAM software users said the cost of the software always is considered but never the sole determinant in deciding which package to buy. The reason for this is that all but the most expensive packages have a short payback with significant potential for improved productivity and profits.

CAM software is one of the most cost effective tools available to machine shop owners/operators at any price. Because Delcam and most of the other developers are competitively priced, cost was not included in this analysis.

Shop managers and programmers interviewed for this analysis unanimously agreed that Delcam’s CAM packages are the best choices for their shops, and they said so enthusiastically. However, the line of software packages from Delcam may not be the best choice available for every shop.

Company Profile

Delcam Plc’s corporate headquarters is in Birmingham, England, with North American sales and support offices in Ontario, Canada, and Salt Lake City, Utah. It offers a suite of 11 different Computer Aided Machining (CAM) and related software packages. Most of the packages were developed by Delcam, but two, FeatureCAM and PartMaker, recently entered the Delcam suite by acquisition.

Delcam products: A quick reference

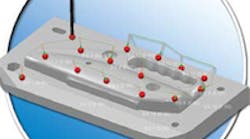

Delcam’s flagship product, PowerMill, is a full-featured CAM power toolkit capable of generating toolpaths and G-code for any type of machining, including high-speed and simultaneous 5-axis machining. It is a process-oriented package which requires going through a lot of manual operations in order to achieve maximum results such as cycle time or surface finish targets.

It is for CNC programmers who want to control every aspect of the machining process.

Delcam’s FeatureCAM software also is a powerful CAM package but is designed to be used primarily as a “check-the-box” program generator by which the software determines how the part will be machined. It makes it very easy and automatic to generate toolpaths but may have a limited ability to achieve some maximum results the way PowerMill can.

FeatureCAM is a software program that was acquired by Delcam, and Delcam has been enhancing it to give it an interface similar to other Delcam products and to use some of the more powerful and sophisticated 5-axis machining capabilities of PowerMill. It is an alternative approach to generating CNC code, not a replacement for PowerMill.

The company’s PartMaker software also is a recently acquired package, and has been enhanced to look like other Delcam products. It is a mature package designed to be used on Swiss-type machines but also can be used for general machining on other machines.

Delcam’s PowerShape is a Computer Aided Design (CAD) and modeling package that can be used in concert with other Delcam software to provide seamless transfer of data from designer to machinist.

PowerInspect is a product that brings the ease of use of CAM packages to the inspection process. It is used to develop consistent inspection methods that can be used throughout the prototyping, manufacturing and assembly processes.

ArtCAM is a unique product that can be used to machine parts from 2D artwork.

DentMill is a CAM packaged optimized for use in machining dental crowns, implants and other items for the dental industry.

CopyCAD is used in reverse engineering to give users control over point cloud data sets in order to go quickly from the physical to the digital world.

Crispin is another suite of CAD software modules that provides a different approach to design. <<