The digitalization of business processes is driving the competition in manufacturing markets, and this is nowhere more obvious than on the plant floor. Automation, robotics, sensors, and different software solutions have completely changed how people interact with equipment and how components and products are created. Manufacturers with high operational costs have a significant incentives to pursue digital transformation.

However, once that decision has been made those manufacturers are faced with a double-edged sword of risk and reward. While automation and digitalization promise a high return on investment, the transition process comes with big upfront costs and nobody can guarantee a smooth ride.

Here are a few sinkholes they will need to avoid in order to maximize the chances for successful digital transformation.

Getting the necessary buy-ins. Ensuring the necessary buy-in comes in two parts: budget approval and change management.

This is a situation where the organization’s top managers must be all-in. There are going to be upfront costs, there are going to be ongoing implementation costs, there is going to be some decrease in output while the changes are rolling in, and there are almost certainly going to be some unforeseen expenses. Top managers need to realize all of that, allocate the necessary budget, and show the commitment to pursue this project up to its completion.

The second part is getting buy-in from all other employees. This is often discussed under the term “change management” and it is a challenge for any organization that undertakes digital transformation. Industrial organizations might have additional struggles in this regard, as they will have to replace long-standing legacy systems and push workers to change their workflow, which may have been established for decades now.

We have seen this first-hand in manufacturing maintenance departments. One organization implemented condition monitoring technology to measure asset health and develop better digital maintenance calendars. However, for a few different reasons the technicians and mechanics never fully adopted the tools. The bottom line is that the organization invested capital to acquire technology they barely used.

To ensure that does not happen, top managers must involve all employees in the digital transformation process, explain what is being done and why, and show how these steps will benefit them as workers and the organization as a whole. The right people must be given the right responsibilities -- and even offered incentives for jobs well done.

Setting the right goals, strategy, and pace. The technology itself should not be a driver of change; that’s what the goals are for. In other words, you are not implementing new tools simply because there are new tools available in the market. You are implementing them because you are trying to reach particular goals.

There are many different things that an industrial organization can aim to digitalize and automate. The success of the implementation will depend on how well the organization establishes a realistic plan of action.

First, you look at the goals. By knowing what you are trying to achieve (and the budget you have at your disposal), it is going to be much easier to select which business processes need to be transformed and what kind of technology needs to be implemented.

After that list is ready, the strategy must outline the priority of changes. In the industrial environment, one of the common mistakes is trying to get everything done at once. Management underestimates the level of impact that changes in one part of the organization can have on other departments. Changing everything at once, especially for highly interconnected systems, can cause a lot of disruption and delays and can overwhelm plant workers.

Digital transformation is a process that can continue for several years and should be treated that way.

Managing and securing data. Organizations that use old legacy systems and do not run on modern software solutions struggle to fully utilize all of the data that becomes available when they go through digital transformation. Real-time asset monitoring, predictive maintenance algorithms, CMMS logs, machine performance data -- the amount of data that opens up through IoT technology and digital transformation can be overwhelming. Suddenly, plant managers do not only need data analysts, but they need to expand their IT department to keep everything running smoothly.

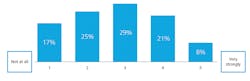

One Deloitte Industry 4.0 study asked manufacturing companies to what extent they are making use of the opportunity to analyze machine data, for example, to avoid defects in the production process. (Chart 9) As you can see, only a few organizations are fully utilizing the data that is available to them.As digitalization moves forward, it would be surprising to see more and more software platforms on the market that can integrate with different apps and sensors and serve as centralized platforms for all plant data -- as CMMS already does for all maintenance data.

Securing the data is almost as great a challenge as managing it. The more industrial business processes rely on data, automation, and software, the more are they exposed to cybersecurity threats.

One way to combat that threat is by running everything through internal company servers. However, a much simpler and cheaper approach is to work with reliable software vendors to make the most out of the cloud-based technology. The final decision should be based on a case-to-case basis after running a cost risk analysis.

Bryan Christiansen is the founder and CEO of Limble CMMS. Limble is a modern, easy to use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organize, automate, and streamline their maintenance operations.