Live tooling added to new technology equals growth for door hardware manufacturer.

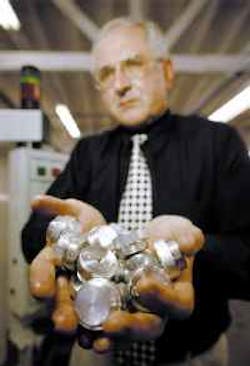

Jackson Corp.'s director of operations, Sydney Cap, displays completed end caps after reducing the cycle time for two caps from 2 min to 95 sec.

Using live tooling on a Haas HL-1 lathe, Jackson Corp. is able to face, turn the O.D., thread, groove, drill offset holes, tap, and cut off a pair of end caps in a single setup.

These end caps required a second setup on another machine to drill a pair of off-center holes. With live tooling, all operations are now performed in a single setup.

The addition of CNC has helped many high-volume producers machine more parts at a lower cost. Such was the case for Jackson Corp., a manufacturer of door hardware. Jackson, however, went a step further, streamlining its CNC operations with live tooling. The move cut out a secondary machining process, knocking 25 seconds off a 2 min cycle time.

For more than 50 years, this Los Angeles based manufacturer has produced high-quality door hardware for the aluminum and tempered glass door industry. According to Mark Warden, operations manager, Jackson was forced to rethink the efficiency of its operations when its main U.S. competitor decided to cut production costs by subcontracting overseas.

"Manufacturing offshore to reduce production costs was never an option we considered," adds Sidney Cap, Jackson's director of operations. "The owner of our company believes so strongly in supporting the local economy, that he established a corporate policy mandating that we buy locally. Satisfying our needs domestically at an affordable price is difficult at times, but worth the effort."

So, instead of going offshore to remain competitive, Jackson opted to modernize and streamline its operations. "We decided to apply intelligence rather than just cheap labor," says Warden. "It is the only way to compete against wages of fifty cents a day. Keeping production in-house also allows us to control the manufacturing process in order to make sure the quality of our products remains high."

Based on a philosophy of "investing in profits," Jackson's modernization plan centered on consolidating the machining processes into a single area and purchasing two machining centers. Before the upgrade, Jackson was manually machining components in four different buildings, and the only CNC machine in use was an old Miyano lathe.

Shortly after acquiring a new Haas VF-1 vertical machining center and a used VF-0 machine, Jackson's production increased by 60 to 70%. "Before bringing in the new machines, we were producing 300 to 350 complete overhead concealed closers a day," says Cap. "Now we average 500 a day. By the end of the year, we project our output will reach 900 units a day."

Warden adds: "The CNC equipment is letting us rethink how we manufacture. It is allowing us to grow the business without having to substantially increase manpower, which allows us to be more competitive and win more market share."

After the two Haas vertical machining centers were installed, it became more apparent that the old Miyano lathe could not keep up with production of end caps for the overhead concealed closer. So, it was replaced with a Haas HL-1 CNC lathe.

"The CNC lathe we replaced was old and dirty," explains Cap. "Our operators were suffering because they had to breathe the fumes, and there wasn't a path through the system for the chips. Our guys had to work much harder, and the required accuracy was difficult to maintain. You can't make good quality parts on old machinery."

The HL-1 helped solve the problem, but completing the end caps still required a secondary process on a mill to drill two offset holes into each cap, which took extra time to set up and run.

After running the lathe for several months, it was decided that live tooling was the answer to the secondary process problem. Haas engineers were brought in to work with plant personnel to add live tooling to the lathe. "It worked great. With the live tooling option, we eliminated one operation and all the additional handling," states Cap. "Each overhead closer needs two end caps, which used to take two minutes of machine time and two operations. Now both operations are done in 95 seconds on a single HL-1 lathe. We face it, turn the O.D., thread, groove, drill offset holes, tap, and cut off. It goes in as an aluminum bar and comes out as a finished component." Warden believes the HL-1 lathe equipped with live tooling is giving them the potential to grow. In order to reach the goal of 900 over-head concealed closers a day, 1,800 end caps need to be completely machined each day. This translates into 600 per shift with a three-shift schedule. To meet the challenge, the HL-1 is equipped with a chip conveyor and has been teamed with a CNC Enhancements automatic barfeeder with a rack capable of holding 12-hr of stock.

As an added benefit, Jackson's programmers now utilize the customizable macros on the Haas control to program tool life and the number of pieces running through the barfeeder. This makes it possible to run unattended on the third shift.

"Made in America still means something, especially to our international clients," Cap explains. "We are proud to say Jackson Corporation sells American products manufactured on American equipment. We expect the same commitment from our vendors and equipment suppliers, which is why we returned to Haas for two more units. A VF-4 vertical machining center and another lathe with a barfeeder have just been installed and are cutting parts around the clock."

Automation keeps Jackson Corp. growing and in synch with its commitment to support the local economy. The company is already talking about robotics and pallet systems as its next step to remain ahead of the competition.