Recent improvements to Kaiser Tool Co.’s THINBIT series will be the highlights of its IMTS exhibit. This includes the FORM-A-GROOVE tooling and the Groove ‘n Turn line for machining Static O-Ring grooves.

FORM-A-GROOVE can customize form tools that will generate complex profiles in a single plunge. These tools may consist of combinations of simple grooves or more complex combinations of grooves, arcs, angles, convex and concave radii. Tools can be composed of stacks of individual inserts or a single carbide block up to 2” wide.

Toolholders are available in 1” round and 1/2”, 3/4” and 1” square for internal and external applications. FORM-A-GROOVE can be coated with TiN, TiCN, TiAIN or Diamond film coatings.

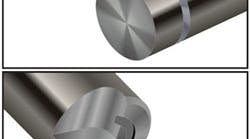

The GROOVE ‘N TURN line will be exhibited also, including dovetail grooving inserts. Dovetail grooving inserts are used to machine O-ring dovetail grooves with 66 undercut angles. The insert design is optimized for strength by utilizing a left/OD and right/ID insert pair to generate the groove form. Insert sizes are 0.030”, 0.070”, 0.090”, 0.100”, 0.125” and 0.150” with major diameters starting at 0.300”. Available in sub-micron grain carbide grades for ferrous and non-ferrous materials either uncoated or with TiN, TiCN, TiAIN or diamond film coatings. GROOVE ‘N TURN dovetail inserts can be used on conventional, Swiss and CNC machines.

Toolholders are available in square shank size 5/16” through 1-1/4” and round shank sizes ” through 1” with straight and 90o presentations. GROOVE ‘N TURN dovetail inserts fit existing “L” series THINBIT toolholders.

An addition to the Groove ‘n Turn line for machining Static O-Ring grooves will be shown. Available in OD and face grooving styles, these inserts feature a 7 included angle and are available in two grades of sub-micron carbide. Companion toolholders and a full range of coatings are available, too.