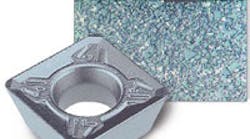

Insert grade X700 is the newest addition to ATI Stellram ‘s (www.atistellram.com) X-Grade technology milling cutter inserts.

New inserts are coated with TiAlN by physical vapor deposition (PVD) and are designed for milling stainless steel and titanium alloys.

The inserts are designed to generate low pressure and stress during machining.

The company said coupling the X700 grade with new insert geometries is especially effective for machining aerospace alloys, and recommends that high cutting speed and low cutting feedrates be used for these difficultto- machine materials.

ATI Stellram said the X-Grade technology uses a substrate of ruthenium with a cobalt binder, and offers superior thermal-cracking and propagation resistance, metal-removal rates that are three times higher than conventional cutting tools and longer tool life. The inserts are available in a variety of styles — square, round and octagonal for a variety of applications.