GE Aviation this week started certification testing for its GE9X engine, a high-bypass turbofan engine being developed for Boeing’s 777X aircraft. The tests are being carried out at the Peebles (Ohio) Test Operation, and follow more than a year of “first full engine” testing (FETT.)

The GE9X It will be a further development of the GEnx engine developed for the Boeing 787 Dreamliner, and itself a modification of the GE90 engine. The first test runs were completed in April 2016. IHI Corporation, Safran Aircraft Engines, Safran Aero Boosters, and MTU Aero Engines AG are participants in the GE9X engine development.

GE Aviation explained that the first round of certification tests are being conducted on the second GE9X “production configured” engine. The FETT sequence generated a volume of critical data on the full engine system and aerodynamic performance, mechanical verification, and aero thermal system validation. Those tests were concluded earlier this year with a series of preliminary, natural-icing tests, in which the GE9X ran more than 50 test points and accumulated 168 hours and 162 cycles.

"Completing a full year's worth of validation efforts on the FETT engine gave us great confidence heading into the certification program with the second GE9X engine," stated Ted Ingling, GE9X general manager. "By incorporating all the ‘learnings’ from the FETT engine, we start the GE9X certification program with a stable configuration and position ourselves to meet the schedule and performance expectations of our customers from Day 1 of service entry."

As testing begins on the second GE9X engine, assembly of the third and fourth engines is in progress at the GE Aviation plant in Evendale, OH.

A fourth GE9X engine is slated for installation and flight tests aboard a 747-400 flying test bed later this year.

An important aspect of the engine’s design is the extensive application of ceramic-matrix composite (CMC) materials as the fan case and carbon-fiber composite fan blades. The lighter materials will reduce overall engine weight, thereby promoting fuel efficiency; and minimize the effects of heat on engine performance, which is considered an important advance in jet engine design.

Last October, GE completed the second phase of GE9X CMC component testing in a GEnx demonstrator engine, accumulating 1,800 cycles and exposing the engine to dust and debris similar to the operational environment. It noted the level of debris exposure was equivalent to about 3,000 takeoff and landing operation cycles.

For that second round of tests, the GEnx demonstrator engine used the same CMC combustor liners, HPT stage 1 shrouds, and HPT stage 2 nozzles from the first round of tests run in September 2015, along with newer HPT stage 1 nozzles formed in CMC.

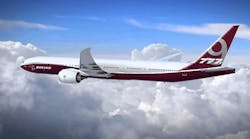

Boeing reportedly has over 300 orders for the new 777X, which is planned for delivery no sooner than 2019. This will be a redesigned version of the 777, the long-range, wide-body jet that is the world’s largest twin-engine aircraft. Correspondingly, GE Aviation indicated it has “almost 700 GE9X engines on order.”