Fasteners are critical components in engineered systems and structures, from aircraft to cars and trucks, to industrial machinery, and for the manufacturers that produce fasteners it is critical to inspect those parts to ensure zero defects, whether for safety, mission-critical performance, or to optimize the manufacturing process. Conventional methods to do this exist, including sorting mechanically for size, or hand sorting with optical comparators, and yet traditionally it has been difficult to inspect internal threads: tiny defects like chips, tears, or weld splatter, as well as short or missing threads, can lead to part rejection, or worse.

Inspecting the vertical walls of a fastener hole and its threads is difficult for the human eye due to the small size, as well as the problem of applying lighting and gaining a proper vantage point for viewing. Not only is such an inspection process slow, labor-intensive, and subject to interpretation, it is prone to human error, too – particularly over long periods when fatigue can degrade effective performance.

“Because many of our parts are safety-related, such as small fuel fittings and unions for the auto industry, our customers will not accept anything but 100% quality, so we carefully check key areas including internal threads,” according to Chuck Abbate, vice president of Operations at H&L Tool, an ISO-TS 16949:2009 registered manufacturer of precision turned and cold formed fastener products, in Madison Heights, Mich. “We needed a way to make sure that all the internal features were perfect and within the print.”

However, even typical cameras and laser-based equipment have difficulty detecting the internal features that are required on many parts, and as the hole or recess becomes deeper the challenge to inspect those features becomes greater.

“One of the problems that arises when looking at internal features on a machine is the different color in the plating and different lighting,” Abbate explained “It is very important to get a machine that determines what it is looking at, that it is truly looking at the part, and not at glare or a shadow.”

Lately, the ‘zero defect’ objective has encouraged developers to conceive and introduce higher-speed sorting technologies, which has encouraged some fastener manufacturers to leave behind the slower, less reliable inspection methods.

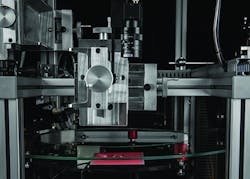

For instance, to make certain that H&L Tool’s couplers, tube nuts, and internal female nuts contained zero defects, Abbate and his colleagues tested a high-speed vision-based measuring machine called the GI-100DT, developed by General Inspection, a source for high-speed measuring and sorting systems for inspection.

The GI-100DT uses a series of front and backlit cameras to calculate a part’s height, profile, and inner and outer diameters. As configured for H&L Tool, the device also has a number of advanced options. These include cameras to check for internal threads, an axial viewer that detects surface imperfections on multiple sides of a part at once, and eddy-current capability. The latter makes it possible to check for metallurgical defects along with plating or hardness variations.

With 360° internal-thread inspection capability, the GI-100DT device incorporates hole inspection optics specifically to image and measure both the bottom of a hole and its vertical walls. This gathers a very high level of detail regarding I.D. threads and the detection of very small defects, like weld splatter, torn threads, reamed threads, chips in threads, short or missing threads, as well as a single damaged thread.

“It is the only sorting machine I have seen that has the capability to totally look inside the part,” said Abbate. “The different types of special lenses on these cameras are very good at looking at all the internal features, which we could never get on a machine before.”

He further detailed how well the machine performs at distinguishing the interior part features from glare or shadow. He noted in particular a glass-top dial table, which stabilizes the parts during inspection while allowing views from the top and bottom at once. Such part stability improves image analysis, data capture and precision, while simultaneous top and bottom viewing speeds the process.

“It is all about the presentation, of how the machine presents the part to the cameras,” said Abbate. “Because the parts stand straight up on the glass dial that the parts ‘ride’ on, cameras with convex lenses can look straight down at the parts and see 360 degrees around, from either side. That way, with 100% sorting, we don’t miss anything.”

He also said that a conventional V-track model inspection machine, with a 30-degree incline to drop the part, would have limited how much of the part interior is visible.

“Other machines cannot look at the sealing surfaces of a coupler, for instance, because they view it at an angle,” according to the shop v.p. “You have to be able to see down in it, which the General Inspection machine has a capability to do.

“With the glass dial table that the parts ride around on, we can view the top and bottom of a part at the same time,” Abbate emphasized. “On a double-featured piece like a union, this allows us to run it through once instead of twice.”

According to Abbate, an axial viewer also allows detection of any surface discontinuities on six sides of a part at once. With such a capability, the camera could, for instance, simultaneously “see” the top and sides of a fastener.

Along with the GI-100DT’s eddy-current capability, which detects any metallurgical defects including plating or hardness variations, Abbate confirmed the device has provided the efficient, zero-defect fastener sorting that H&L Tool has needed.

“We have found our new system to be at least 10 times faster than hand sorting and much more effective than typical sorting machines that look only on the outside of a part,” he concluded.