New sensor puts its John Hancock on real-time torque measurement

Fast’s embedded-magnetic-domain (EMD)-based sensors measure torque at rotational velocities up to 100,000 rpm.

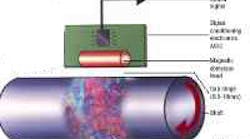

Fast Technology's EMD torque-sensing system consists of a magnetized shaft, the detection head, and signal conditioning electronics.

Typically Fast's torque sensors have an accuracy of 0.5% full-scale. In tests they show no drift or other precision loss after 4 million continuous measuring cycles.

Engineers and operators get an instant overview of a machine's performance by knowing how much torque is produced at the spindle. The problem is finding an easy and efficient way to measure torque, especially in hostile shop-floor environments. For one manufacturer, the answer is a magnetic signature.

Relying upon embedded-magnetic-domain technology (EMD), a new noncon-tact torque sensor uses a combination of magnetic induction and electronic processing for accurate torque measurements in real-world production settings. Basically, the maker of the sensor, Fast Technology of Livonia, Mich., imprints a magnetic signature onto a shaft and then monitors how that signature changes. The magnetic signature has a constant strength in a specific location, and as torque occurs, explains Rhex Edwards, marketing manager for Fast, the signature becomes somewhat distorted. The sensor's detection head, which can be as far away as 10 mm, reads these magnetic fluctuations regardless of dirt, fluids, or other nonmagentic materials. The unit also handles temperatures ranging from -10° to 150°.

"A key to the sensor," says Edwards "is that the magnetic distortion, which occurs as torque is applied, is directly proportional to the sensor's output signal. Changes in the shaft's magnetic signature are then converted into a standard analog output signal." That signal is then sent to a display or a controller based upon the user's needs.

With a display, machine operators have real-time information about a machine's performance. For instance, if a bearing is going bad, causing increased torque, operators can investigate the problem. Without such immediate feedback, a production run may be scrapped, or a machine damaged, before the problem is noticed. When connected to a controller, torque information is instantly available to control power as the user changes cutters, drills, or taps.

The Fast sensor measures torque up to 1,000 Nm (737.56 lb/ft) in shafts rotating at 0 to 100,000 rpm, and it works on range of shaft sizes. Typically, the EMD-based sensors have an accuracy of 0.5% full scale. And in testing, they show no drift or other precision loss after 4 million continuous measuring cycles.

EMD-based sensor installation requires no notable mechanical modifications, but the shaft must be ferrous and contain some nickel. In addition, it should not reach the Curie point during use, nor be exposed to strong magnetic fields. Permanent damage to a shaft can also impact sensor accuracy. But according to Fast, these limitations rarely pose serious problems.

The sensor, at 9 V, draws less than 10 ma, which makes it easy to integrate electrically. "It's just a question of where to put it," says Edwards.

Currently, the company is pursuing dual avenues for integrating its sensor to spindles. First of all, Fast is working on a retrofit solution for existing products where an adapter is put on either end of the sensor unit to connect it to a specific spindle-and-tooling arrangement. The wiring is then run back to the control. By having the sensor wired to a machine's control, operators can establish set points for torque levels using real-time, real-world information rather than relying on feel or an estimate. According to Edwards, a shop should be able to convert a handful of spindles in a weekend.

"The second approach," says Edwards, "is to work with OEMs and spindle manufacturers to integrate the sensor directly into a machine's spindle." For new machines this is the more desirable solution, he adds.

Fast does have a significant amount of work in multiple-spindle applications, specifically drilling and tapping operations. In these cases, shops use the sensor to determine if there is in fact a drill or a tap in the spindle, if it is damaged, or how sharp it is. By monitoring a new tool, shops can learn its wear factor to determine the time it takes for the tool to dull or break.

In addition to spindles, the sensor shows promise in other applications, one of which is electric steering systems. Electric steering replaces all the hydraulic power-steering components of a car with electronic controls. A torque sensor in the steering column relays the direction the steering wheel is turned to an electric motor which, in turn, moves the car's wheels. As compared to hydraulic-based systems, electric steering is less expensive to implement, says Edwards. "Automakers buy thousands and thousands of gallons of power steering fluid. It's a hazardous substance that requires storage tanks, material data sheets, fluid and flow control, and contamination handling. All of that goes away with electric steering," he adds.

For car buyers, automobiles with electric steering are lighter, better performing, and more fuel-efficient because there are no power steering hoses or fluid reservoirs. And not having a hydraulic power-steering pump reduces engine drag, thus improving performance.