A French aerospace machining operation, Gresset and Associates, fulfills its high-tech potential and aerospace requirements with ESPRIT CAM

Not every machine shop is a high-tech operation, but nearly every one has the potential to be one, thanks to the complexity of component parts required in manufacturing even standard work orders — and the demands for precision in process and quality control to complete those orders. Shops need experience and skill to compete for those orders, and they need the technology that matches the high-tech demands.

Founded in 1969 in Nods, France, Gresset and Associates specializes in machining precision mechanical parts for the aerospace, defense and oil and gas industries. It has 49 employees, is ISO 9001- and EN 9100-certified, and is organized around three main markets:

• Components for hydraulic systems, such as spools, splices, and valve seats, that require a high level of manufacturing precision and a high quality finish. Gresset produces these parts from drop forgings.

• Components for safety systems, such as braking systems, as well as spare parts. For example, Gresset produces parts for Safran’s Electric Green Taxiing system (which allows commercial aircraft to pushback from gates and taxi without using jet engines, to reduce fuel volumes.) "Our activity in the aerospace industry is, for the most part, focused on the creation of parts critical for military devices," explained Lillian Lamy, production manager, listing the Rapid Fire, Sight Checking, and ATL2, helicopters.

• High-precision aftermarket bronze bearings and set rings for aerospace manufacturers.

Gresset has introduced Lean manufacturing methods in production, quality management, and industrial planning. Also, it has invested over €1 million ($1.1 million) in five-axis CNC machine tools, computer-aided manufacturing (CAM) software, tooling, and training. The latest capital investment was a Mori Seiki NT3200 DCG mill/turn machine —a two-spindle operations with a five-axis milling head.

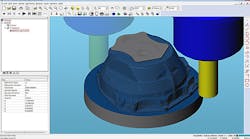

The acquisition of this machine led to another strategic purchase, of ESPRIT CAM software. The programming software that Gresset used previously lacked flexibility, and made it difficult to make toolpath changes.

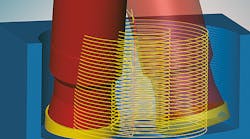

ESPRIT was selected mainly because of its partnership with machine tool builder DMG Mori, which provides advantages like licenses adapted to the machines and post-processors certified by the manufacturer. Other advantages to ESPRIT include its five-axis machining capabilities, high flexibility, and open post-processors, its functionality with all of Gresset’s machines. The software program's simulation tools help to optimize programs and save machining time.

Usicam, a partner of the ESPRIT distributor Usiprog, assisted with the implementation process. A training session lasting a few days, followed by the use of video tutorials offered by Usicam allowed programmers to work on real-world applications and familiarize themselves more quickly with the program. "We are particularly appreciative of how Michel Horning, the Usicam representative, has been readily available to support us,” said Gresset’s programmer Gilles Noirjean.

The programmers used ESPRIT for the first time to machine a complex hydraulic spool in stainless steel, an Airbus A350 part. It required turning and milling operations on all sides. The two-spindle, two-turret NT3200 machine with B-axis milling was programmed successfully in three hours. "With our previous manufacturing software, we had to go through several post-processors to obtain all the tool paths. With ESPRIT, one post-processor allowed us to generate all of the turning and milling paths.” He noted the CAM’s effectiveness reduced programming time by 25%.

They also programmed a three-axis Spinner VC810 machine to produce aluminum parts needed in a food-processing machine. ESPRIT reduced programming time by 30%, and made it possible to modify the program to product different part numbers very quickly.

Usicam helped install a database of cutting conditions for the materials used most often by Gresset. Usicam also supported Gresset by developing an application for programming new variants in a family of commonly machined parts. This application has reduced programming time by 60% compared to the previous CAM system.

"The creation of standard machining methods that can be re-used for new programs has saved substantial amounts of time,” stated Lillian Lamy. “Collision detection also has helped us to prevent accidents.” In addition, Gresset technicians appreciate how easy it is to manage tools in ESPRIT, with a base library that can easily be enriched with the addition of specific tools.

The combined advantages of the new mill turn machine and five-axis technology have been a huge step forward for Gresset, helping it to fulfill its high-tech potential, and the shop’s management is fully satisfied with the investment and with the service provided by the USICAM team.