The development of CNC machines is proceeding according to two objectives at the same time: complexity, in terms of part geometries and machine movements — and efficiency, in terms of production time and energy and material savings. The progress is extraordinary, with one exception: machine programmers must keep up with the development every step of the way.

CNC Software is on to this with its new MasterCAM Swiss Expert program, a CAM program it indicated is suited to the current state of manufacturing technology, as well as the demands on the machine programmer.

Simply, CNC Software posits that the current standard for complex machines means that manual programming is no longer efficient or even feasible for some part designs. Mastercam Swiss Expert offers support for five-axis Swiss machines now available, simplifying the complex task of programming five axes of simultaneous motion.

Importantly, this capability allows part designers more freedom to add complex features, with the confidence that a CAM program like Mastercam Swiss Expert and the latest generation of Swiss machines can execute the job.

Mastercam Swiss Expert is entirely solids-based, so creating toolpaths from solid faces, edges, loops, and turned profiles is done quickly: there is no need to create additional geometry to cut a part, the developer noted.

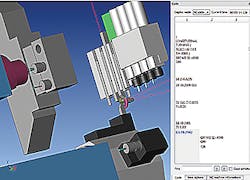

Moreover, explaining that “efficient cutting means more than just programming a toolpath,” Mastercam Swiss Expert presents programming tools that shape the entire process, including a thorough routine for streamlined programming, from toolpaths to synchronization to simulation; functions for tool selection and build 3D tool assemblies in the comprehensive Tool Manager. Tools, tool assemblies, and tool equipment are fully supported in Machine Simulation.

Also included are functions for saving tools and cutting strategies into libraries, for future use on similar or families of parts. Programmers can view their operations and add synchronization points graphically using the Sync Manager.

Importantly, Mastercam Swiss Expert recognizes programmers’ machining modes, so it will prevent adding sync points that the machine cannot execute.

Simulation is an important phase in toolpath development, and Mastercam Swiss Expert lets programmers simulate projects “fully and safely” on a virtual machine before any machining is scheduled.

Swiss Expert’s simulation is capable of full simulation of every moving component of a machine, including material, main and sub spindles, all tool holders, and part handling devices. In addition, it has automatic collision detection, so mis-runs will be identified in a virtual environment before damaging materials or equipment.

The simulation allows programmers to ‘jump’ any point in the simulation automatically by selecting a location on the Gantt chart. Also, it’s possible to view the NC code for all channels simultaneously while the simulation is running.

As for programming efficiency, Mastercam Swiss Expert has various tools necessary to optimize part cycle times graphically, and avoid collisions. With the Sync Manager, programmers can use an unlimited number of channels; drag, drop, and sync one operation to another; sync operations by tool group or by channel; and view all machining parameters and modify them on the fly, if necessary.

Additionally, programmers can expand and contract the timeline for viewing the part process; use colors to help identify which toolpaths belong to which tool group or channel; and view the time each operation takes to complete.