CNC Software Inc. is releasing Mastercam X8, the latest update to its Windows-based CAD/CAM platform, a new suite the developer said introduces program tools that improve process speed, automation capability, and production efficiency for all machining jobs. Mastercam is a software program for for 2- through 5-axis routing, milling, and turning; 2- and 4-axis wire EDM cutting; 2D and 3D design; surface and solid modeling; artistic relief cutting; and Swiss machining.

In addition to the performance improvements, the developer reported Mastercam X8 introduces new solids features, UI improvements, and usability/workflow improvements, among other new functions.

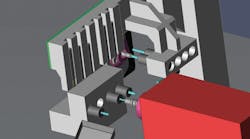

For example, Mastercam called its new Dynamic Motion technology “a new and exciting approach to creating toolpaths,” that follows proprietary rules reference a broad data set to create the most efficient cutting motion possible. “Dynamic toolpaths calculate not only the area where metal will be removed,” according to the developer. “They also take into account the changing condition of the material throughout various stages of machining. “

The Solids interface and workflow have been fully revised for Mastercam X8. The result is simpler, more intuitve building and editing of solids programs. All existing Solids functions have been updated to reflect the new workflow, too.

As well, with the new Solids interface there are new features such as Live Preview, Hands-on Drag Controls, and Direct Editing has been improved to simplify model preparation.

CNC Software continued, explaining Mastercam X8 has improved usability and customizability for the way programmers and operators work. Panels can be automatically hidden, docked to either side of a window, or undocked and placed outside the Mastercam program. The graphics display is upgraded with a simpler aesthetic and more responsive selection, with an improved look and feel. New icons present a consistent, modern color palette that is “colorblind friendly,” the developer said.

Other new tools in available in Mastercam X8 include:

• Improvements to 2D high-speed toolpath generation;

• New ability to define and select reference positions for approach and retract moves in mill-turn operations;

• A new strategy for multi-axis roughing that simplifies the task of creating multiaxis pocketing toolpaths, to rough-out pockets based on a floor or ceiling shape;

• Lathe toolpaths can be included in stock model operations, which can be used for subsequent milling operations; and

• The new Contour Roughing toolpath is designed to take passes parallel to chained geometry.