Autodesk was well established as a 3D design program for architecture, engineering, construction, manufacturing, and other industries when it purchased HSMWorks in 2012. That move signaled its intention to project its design expertise into manufacturing process design and control. (Autodesk’s CAM embrace is continuing with the developer’s recent announcement that it will take over Delcam plc and its portfolio of CAM platforms, for $277 million.)

A more practical expression of the convergence of CAD and CAM came with HSMWorks’ recent rollout of HSM 2014, its seventh update. The developer highlighted the new CAM’s compatibility for manufacturers regardless of their CAD source files, but particularly the programs from Autodesk rival SolidWorks.

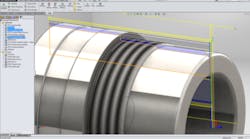

HSMWorks is an integrated CAM program focused on CNC milling and CNC turning, available exclusively for SolidWorks customers using SolidWorks 2012 or newer.

HSMWorks 2014 will be available in two tiers: HSMWorks 2014 Professional supports 2.5D, 3D, and 3+2 milling and 2D turning; and HSMWorks 2014 Premium supports 2.5D, 3D, 3+2, and 5-axis (or multi-axis) milling and 2D turning.

The new release also includes an update to HSMXpress, a free CAM program that uses the same CAM kernel, 2.5D milling and drilling strategies, simulation, and post-processing system as HSMWorks -- and it also works as a CAM tool for basic machining. (HSMXpress 2014 supports 2.5D milling only.)

The developer declared HSMWorks 2014 its most advanced release to date, noting it includes several enhancements and new functions for SolidWorks users. Among these are:

• Machine Simulation. The new program supports a wider range of machine types, including 5-axis machining centers. Using native SolidWorks assemblies means users are able to model their machines within SolidWorks software, without having to import STLs or dumb solids.

• HSMWorks API. The new API gives users with the ability to automate many programming tasks, including toolpath generation and post processing.

• Adaptive Clearing 2.0. Adaptive Clearing establishes efficient, high-volume material removal using constant tool engagement to reduce cycle times, tool and machine wear, and produce quality finished parts. Better support for multi-core processing and improved linking make Adaptive Clearing 2.0 an exceptionally advanced adaptive roughing technology.

• Enhanced Turning support. New options have been added to HSM Works that give users greater control over toolpath creation, including finer controls over leads and transitions, overlaps, roughing, and finishing passes. Also, turning toolpaths have been optimized to reduce machining time by improving linking and ordering, as well as control over home and retract positions.