JETCAM International — developer of the Expert CAD/CAM software platform — recently relaunched its Jetcam Orders Controller software (JOC) for end users, following a “ground-up rework” that it said delivers a user-installable product that requires less than 30 minutes of training.

The developer introduced its CAD/CAM platform in 1986 and now notes it is in use in over 80 countries. The Expert software supports a vast range of CNC punching, laser, plasma, routing, waterjet and flatbed cutting machines, meaning users can program multiple combinations of CNC machines with a single CAM system.

The new version of Jetcam Orders Controller, JOC Lite II, allows users to create order lists of either components or complex assembly structures, remotely, and then send them to the Expert CADCAM software for nesting. The new software is delivered with over 20 tutorial videos that guide users through all stages of setup and usage, and only requires paths to be set up to point to the user’s Jetcam installation and geometry files.

Once JOC Lite II is installed, users can create unlimited worksheets, e.g., for different operators, machines, days, etc. Dragging and dropping components or complete assemblies onto the worksheet can populate these worksheets. Or, the programmer can use CSV import to create and populate worksheets automatically.

Drop-and-drag programming

Complex assembly structures are easy to create. Users start by creating their assembly and sub-assembly names and arranging them in their depth order. Then, they drag and drop components into any level of the assembly and specify quantities. The assembly is then ready to order. Complex assemblies that are multiple levels deep can be created automatically using files in directory structures: the user right-clicks over a folder and selects “Create Assembly,” and the assembly is available to order immediately.

Worksheets can be queued for nesting, too. Each sheet is sent for nesting as soon as Jetcam Expert reports back that the previous nest is completed. Comprehensive tagging and untagging options allow users to select or deselect all items within a given group or filter, which is useful for selective ordering from a large list of components.

Users are able to customize their views in various screens. Each screen has a pullout tab that displays additional information. Users can choose to leave each tab open or closed, and these settings will be stored in the program memory.

Displays of components, assemblies, orders and nests have their own filters and/or groupings, so limiting or grouping the information displayed is just a quick step. For example, within the orders tab users can group orders by material, thickness, material and thickness, machine to be cut on, order ID, or delivery date.

Also, a search field allows users to locate components quickly across all scanned directories.

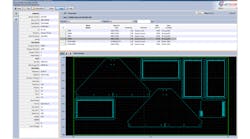

The nests tab shows all completed nests, displaying a vector view and detailed nest information. (Punching customers also benefit from tooling and clamp information.)

Jetcam Orders Controller Lite II works in conjunction with a single Jetcam Expert license. A Premium version is available too, which builds on this functionality but works with multiple Jetcam Expert systems, provides automatic CAD import, and works with Jetcam’s Remote Control Processing module so Expert can be used as a “black box” — meaning, fully automated generation of nests, NC codes, and reports.