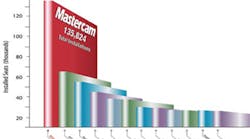

According to the latest analysis of the CAM software market produced by CIMdata, Inc., Mastercam from CNC Software Inc. with more than 135,000 installations, is more than twice as popular as its nearest competitor.

Mastercam is a Windowsbased CAD/CAM package for 2-axis through 5-axis milling and turning, 2-axis and 4-axis wire EDM, 2D and 3D design, surface and solid modeling, and 2D and 3D routing.

The CAD functions are more advanced than what is needed to do simple editing of part files for use with the CAM function.

Some users say that it is more than they need and that the CAD function is more design-oriented than machinistoriented. This made the package harder for them to learn than other packages with only simple editing functions. Other users say that the extended design-oriented functionality of the CAD package gives them the ability to create complex designs without having to buy a stand-alone CAD package.

Even some long-time Mastercam users admit that it was not easy for them to learn to use the package. However, once they became familiar with it they also said they appreciate the power and flexibility the package gives them, especially in designing fixtures and work holding devices that never come with their customer’s part files.

Mastercam has responded to the need to reducing learning time in two ways.

With its latest release, X3, Mastercam now has Feature Based Machining and a simple check-thebox programming option.

The new programming option is so simple and easy to use it was recently demonstrated by a six-year old daughter of one of CNC Software’s executives. The six-year-old created toolpaths to machine a complex 3-axis part using the point and click functions.

Mastercam’s X3 release also has become fully integrated with Dessault Systemes’ SolidWorks 3D CAD package.

SolidWorks is one of the most popular stand-alone 3D CAD packages used by machine shops and manufacturers. Fully integrating Mastercam’s toolpath generation and editing functions into SolidWorks eliminated the need for shops that are familiar with SolidWorks to have to learn the idiosyncrasies of Mastercam’s CAD functions.

The Feature Based Machining function in the X3 release can be used to automatically evaluate a part’s features and to design an effective machining strategy.

CNC Software also says that the new X3 release offers substantially faster multi-axis toolpaths combined with enhanced control, and that they have developed new high speed toolpaths expressly for 2D machining that offer high speed cutting and hard milling, and also offer superior finish and longer tool life.

Mastercam’s strength is in production 2-axis and 3-axis machining, but it does offer 5-axis capability, and at least two of the NASCAR racing teams use Mastercam for their most sophisticated 5-axis machining – the porting of engine heads.

One of those teams – Roush Yates Engines – makes all of the Ford engines used in NASCAR using Mastercam. Whether Mastercam’s 5-axis capability is the best choice for efficiently machining very complex parts used in aerospace and energy applications such as blisks, however, is an open question.

Like many of the other top CAM and CAD/CAM packages, it is sold by module to give the end user the ability to buy and pay for only what is needed to meet current needs, then to add additional modules should other needs arise. Since each module contains two or three levels of features, tailoring a package to a shop’s specific needs — and not paying for features and functions that are never used — is very easy.

CNC Software, located in Tolland, Conn., has been in business since 1983. Its owners, who have always played an active part in the day-today management of the company, say that they are in it for the long haul. They continually re-invest in both product and facility improvement and recently turned their corporate headquarters into a “green,” environmentally-friendly operation.

While Mastercam is the most popular CAM package on the market, does that mean that Mastercam is the ‘best’ CAM package on the market? Not necessarily.

The ‘best’ CAM package on the market, as far as any given machine shop is concerned, is the one that best fills its needs, but with more than 135,000 installations worldwide obviously there are a lot of shops that have said “Yes” to Mastercam.