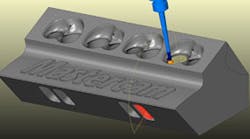

Mastercam’s Port Expert add-on determines roughing and finishing toolpaths to make ports for automotive cylinder head machining.

Machinists and programmers with high-volumes of precision automotive engine work will appreciate a new add-on function from Mastercam: the new Port Expert program that creates toolpaths for cylinder head porting from surface or solid data. Port Expert uses a lollipop tool, and has collision checks for the entire tool — shank, arbor, and holder.

Mastercam is a Windows-based CAD/CAM platform developed by CNC Software Inc. for two- through five-axis routing, milling, and turning; two and four-axis wire EDM; 2D and 3D design, surface, and solid modeling; artistic relief cutting; and Swiss machining.

Port Expert offers several cutting options, such as cutting only the top, cutting only the bottom, or specifying the amount of stock to leave on the entire port. Port Expert toolpaths use three-axis machining as far into the port as possible, and then convert automatically to five-axis motion with minimal tilt. “This leaves no fishtails or inefficient reverse moves,” according to the developer, “and smoothly transitions where the toolpaths meet at the middle of the port.”

The program provides roughing and finishing toolpaths to make ports from castings or billets, and because it can support an unlimited number of surfaces the geometry can be made of multiple surfaces that are “stitched” together.

Additional features include:

• Automatically calculation for optimal tilt angles, meaning there is no need to split the surface or create tool-axis control splines.

• Creating toolpaths on triangulated or stitched surfaces: a one-piece surface is not necessary.

• Simulating step-by-step through the toolpath, demonstrating the motion used in transition at the middle of the port.

• Generating five-axis code that can run any CNC machine.