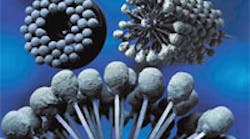

Ball-style hones are highly specialized abrasive tools that are instantly recognizable by the small, abrasive globules permanently mounted to flexible filaments. They are flexible, low-cost tools utilized in the automotive, aerospace, manufacturing and machining industries for sophisticated surfacing, de-burring and edgeblending.

But all honing tools are not created equal. While many share fundamental characteristics, there is a significant quality difference between a generic tool selected from a catalog and a custom-adapted honing tool engineered to meet specialized requirements.

One example of a specialized application is “plateauing,” in which cylinder walls are subjected to a borefinishing procedure that increases the life of both the cylinders and piston rings. Plateauing removes loose, cut, torn and folded material within the cylinder, creates valleys and removes peaks that would otherwise damage rings or seals. With this finishing, more lubricant is retained to improve engine startup and performance.

“The trouble you run into is that no two plateauing scenarios are alike,” explains Jim Huffman, director of engineering, Salem Tools Inc., a provider of engineered manufacturing products and value-added services. “Frequently there’s a finishing problem where the bore is either too smooth or too rough. Ballhoning eliminates such problems so long as the tool is adjusted to meet the requirement of the individual application.”

Brush Research Manufacturing Co. (www.brushresearch.com) has developed the Flex-Hone for diesel engine cylinder deglazing and finishing. General Manager, Don Didier said, “The tool’s unique design makes it ideal for this purpose and for just about any application that calls for the use of a resilient, flexible and soft-cutting honing solution. Available with a broad range of abrasives and grits, Flex- Hones’ independentlysuspended, abrasive globules both self-center and self-align to the bore as well as compensate for wear, all of which facilitate close-tolerance finishing work.”