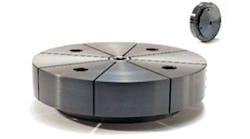

Schunk Inc. (www.schunk.com) said its new Unilock Quick Change Pallet System provides accurate and repeatable setups of workholding fixtures for production run machining and grinding operations. Workpieces can be set and moved through multiple machining operations with a minimum of resetting, cutting setup time as much as 90 percent.

Unilock consists of stationary modules that are installed individually or in multiples directly on a machine’s worktable or tombstone. Existing workholding devices, such as vises, chucks or special workholding fixtures, are mounted on the unit’s clamping plates that mate to the modules. The clamping plates are locked into the modules through a fast-acting (0.2 sec) air-actuated mechanism. Once the clamp modules are set in place, workholding devices are accurately positioned (0.005-mm repeatability) and held securely to the worktable or pallets with clamping forces to 25,000 lb (75,000 N). This clamping force is maintained by a steel spring assembly and does not require air other than for the release of the fixture.

The modules can be mounted on horizontal, angled or vertical clamping plates. Fixturing for operations on horizontal or vertical milling machines is readily accomplished. Because the clamping modules are designed to accommodate existing manual and automated workholding devices, Unilock works well with multiple machines in a work cell, and palletized workpieces quickly transfer from one workstation to another.