Plasma heat-treat process in further development

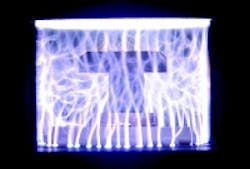

AtmoPlas technology, developed by Dana Corp., generates plasma at atmospheric pressure, without vacuum equipment, to harness microwave energy for joining metal components.

Two heating-treating-system manufacturers will further develop a reported quick and efficient plasma heating technology by an automotive-component producer. ALD Vacuum Technologies AG, Hanau, Germany, will use Dana Corp.'s AtmoPlas technology in manufacturing carburizing systems, and Rubig GmbH & Co., Wels, Austria, agreed to use it in its nitriding processes. Dana completed proof-of-concept and technical and commercial analyses of those processes, and has also agreed to use technology developed by ALD and Rubig in its heat-treating operations.

According to Dana of Toledo, Ohio, the AtmoPlas process generates and sustains plasma at atmospheric pressure — without using vacuum equipment — by harnessing microwave energy and generating temperatures up to 1,200° C (2,160° F). It added there is no known upper temperature limit.

"Dana's AtmoPlas technology has the potential to revolutionize heat treating by significantly reducing costs and improving both efficiency and material properties," says Chuck Heine, president of technology development for Dana.

The component manufacturer recently obtained its first patent for the AtmoPlas technology for joining metal components. The plasma absorbs and focuses microwaves, says Dana, which reduces arching while evenly distributing heat. This reduces thermal shock for metal components. The microwave-absorbing plasma uses 95% of microwave energy to quickly and reliably join metal parts via brazing, welding, bonding, and soldering.

Twenty patent applications are pending in the U.S. on AtmoPlas uses. Those identified include treating vehicleexhaust gasses, generating hydrogen, and creating carbon nanostructures for use in the electronics and medical fields. Dana is working to commercialize more applications such as hardening, sintering, brazing, and annealing. Potential surface-treatment applications include hard-material coatings and plasma cleaning.