If operating speeds top 500,000 DmN, or if the system’s bearings are preloaded, NSK recommends adopting one of three standard run-in procedures.

The bearing design and application experts at NSK emphasize that following a proper run-in procedure will maximize bearing and grease life — and in the long run can save maintenance time and money for an operation. They warn that skipping these crucial first steps may lead to catastrophic failure at start-up by missing out on early warning signs of machine faults. It also may damage the bearings and shorten the grease life.

How do you know when to adopt a run-in procedure? If your operating speed exceeds 500,000 DmN or when bearings are preloaded, NSK recommends one of the following run-in methods. If in doubt, consult NSK before proceeding.

An approximate method of calculating DmN is:

There are three common methods of bearing run-in. The first method, called continuous run-in, gradually increases speed until the final operating speed is reached. This procedure, which can require up to 10 hours to complete, allows the operator to detect potential problems before they can cause damage. Consider using this method for new equipment.

The second method is used for existing equipment that has previously undergone a thorough run-in. This method, called intermittent run-in, can typically be completed in less than half the time as continuous run-in.

The third method is referred to as high speed run-in: it is used only when the speed cannot be varied.

Continuous run-in procedure, variable speed

This procedure is typically done in 10 stages with each stage taking up to an hour to complete. Start by dividing the final operating speed by 10. This value gives us our first stage running speed and becomes the incremental value for each new stage. Table 1 gives an example of this. The temperature must be stabilized before graduating to the next stage.

Intermittent run-in procedure, variable speed

This procedure is typically done in 8~10 stages. If eight stages are being used, operators should start this procedure by running the spindle at 1/8 of the final operating speed for 10 minutes (see Table 2 Stage 1). This first step expels any excess grease and will alert operators to potential problems before they cause damage. Next, begin the process of cycling through incremental stages until full speed is reached and the temperature has stabilized.

Stages two through eight are divided into 10 cycles, each with a duration of one minute. The spindle should be run up to the target speed and held for 15 seconds. Stop the spindle for the remaining 40 seconds and repeat the cycle. See Table 2 for an example of calculating the target speed for each stage.

When 10 cycles are completed move to the next stage and start again. As you progress through the stages, the rest period between cycles will decrease. Figure 1 illustrates the start, run, stop and rest phases of the one-minute cycle.

After completing the last stage, allow the spindle to run at operating speed for approximately one hour to ensure there are no problems. See Monitoring Bearing Temperature before starting run-in procedure.

Continuous run-in procedure, high speed

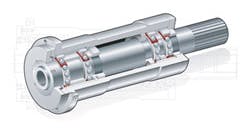

Bearings and spindles represent a significant value in replacement costs, so proper, effective maintenance techniques are critical for machine shops and OEMs.

Use this method only when the equipment speed cannot be varied and you can closely monitor bearing temperature. Run at full speed for 20 seconds and stop, allowing the bearings to cool for 3-4 minutes. Repeat cycle 10 times. Next, run at full speed for 30 seconds and allow the bearings to cool for 3-4 minutes. Repeat cycle 10 times. Increase run time to 40, then 50 then 60 seconds, running through each cycle 10 times and allowing the bearings to cool 3-4 minutes after each run. See Monitoring Bearing Temperature before starting run-in procedure.

Oil mist and oil air systems

Oil lubrication is not exempt from run-in procedures. New equipment and equipment left idle for long periods can be run at 1/3 of their operating speed for 2-3 minutes before being run up to full speed. This simple procedure will get rid of any excess oil built up in the lines or has collected around the bearing.

Monitoring bearing temperature mist and oil air systems

Stabilizing the bearing temperature at an acceptable level is critical to a successful run-in procedure. Before moving to the next stage, the temperature should be constant, or dropping. If at any time the bearing temperature exceeds 70°C (158°F) stop the process and allow the bearing to cool to 40°C (104°F) before continuing. Ultimately, the target constant temperature, when measured at the housing, should be 50°C (122°F) or lower. Temperature rise with cylindrical roller bearings is typically faster than ball bearings. Do not attempt to hurry the process by blowing air over the housing as this will cause an excessive internal preload and may damage the bearing.

When you consider how much effort and expense goes into the manufacture and setup of precision bearings and machine tool spindles, it’s not surprising that a proper run-in procedure takes time. Think of it as maximizing your returns.

For more information contact NSK at 1.88ThinkNSK (1.888.446.5675), or visit www.nskamericas.com