Thomas Sveda

Charleroi, Pa.

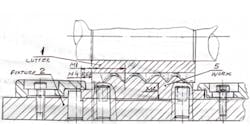

When metric threading on an English lathe, I can not use the thread dial to pick up the metric thread lead, and it is not always practical to keep the half nuts engaged at the end of the cut. In these occasional metric situations, I reverse the chuck and run the carriage back to start the next cut.

I incorporate this method where the half nuts are first engaged for the desired start cut location. I then rotate the chuck by hand to remove any slack in the gear train and leadscrew.

At this point, I match mark the chuck to the headstock and leadscrew to the gearbox. I then mark the carriage location on the bed or use the carriage stop on the tailstock side of the carriage for right hand threads.

I take the first cut, disengage the half nuts at the end of the cut, move the carriage back to the mark on the bed, and rotate the chuck until the match marks for chuck and leadscrew align exactly. Now with the half nuts engaged, I am ready for the next cut. Remember, it is extremely important that all the marks are in exact alignment at the start of each cut.

www.aminfo.biz/417.ad