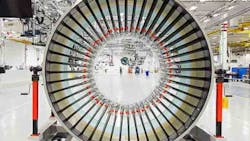

Jet engine builder Pratt & Whitney has inaugurated what it described as a “new, state-of-the-art” manufacturing plant in Middletown, Connecticut, where it produces PurePower® PW1100G-JM engines for the Airbus A320neo commercial jet, and the F135 engine for the F-35 Lightning II Joint Strike Fighter.

The multiyear revamp effort was previously described by Pratt & Whitney as a four-part rehabilitation project at Middletown, its main production center. It installed new assembly lines and test cells, and implemented some advanced new production processes. Among these is a horizontal, moving assembly line for PW1100G-JM engines, which will allow the OEM to increase production volumes.

Middletown’s F135 production line has been “streamlined” to improve the flow of production, changes that involve new tooling for more efficient, high-volume assembly while maintaining high safety and ergonomic standards.

The horizontal assembly system was developed by Pratt & Whitney after benchmarking several automotive and airframe manufacturers. Increasing production volumes for F135 engines is important to meet the F-35 program’s production rate increases, which are scheduled to rise more than 100% by 2020.

"The system has both vertical lift and rotation capability," explained Tom Mayes, general manager for Engine Centers and Compression Module Centers. "It is also programmable so teams at our sites can automate the line depending on volume and move the carriage systems at the rate of output to adjust for customer demand."

The OEM also said the improvements at Middletown would include new and revamped production space for the V2500 and PW1100G-JM high-bypass turbofan jet engines (both destined for the Airbus A320 series.)

Fully assembled engines will be tested at Middletown too, using some new test cells. Technological and structural improvements will reduce the time it takes to set up and complete engine testing.

P&W has not announced the cost of the revamp, describing it instead as a “significant” capital investment.

"Pratt & Whitney is transforming its global operations," stated Joe Sylvestro, vice president of manufacturing operations. "We're investing more than $1 billion worldwide to prepare for production increase for the F135 engine and PurePower engine family, including significant investments in our East Hartford and Middletown facilities, and our new horizontal engine assembly system.”

He continued: “Advanced technology development and production, like the PW1100G-JM, F135 and V2500 lines, build on our legacy of success and position our company as a leader in advanced manufacturing."

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.