Jet engine builder Pratt & Whitney’s PurePower® Geared Turbofan™ (GTF) engine has been cited as an “aviation climate solution” by the Air Transport Action Group, a coalition of aviation industry companies and organizations that promote the “sustainable” technologies. The recognition came at the Global Sustainable Aviation Summit in Geneva, Switzerland.

The ATAG published a collection of 100 similar CO2 emission-reducing technologies available now for aircraft OEMs, a series also titled Aviation Climate Solutions.

"Aviation plays a vital role in the world economy, providing connectivity for people and business," stated ATAG executive director Michael Gill. "Our industry has also taken a lead in climate action, putting in place a comprehensive framework and goals to reduce emissions from air transport."

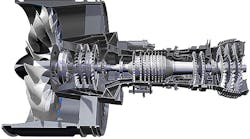

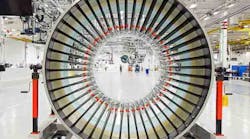

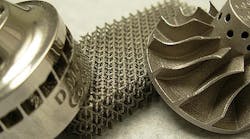

The PurePower GTF is a jet engines designed with a gear system separating the engine fan from the low-pressure compressor and turbine, so that each module operates at optimal speed. This means that the fan can rotate more slowly as the low-pressure compressor and turbine operate at a high speed, increasing engine efficiency and reducing fuel consumption, emissions, and noise. The engine builder also indicated that increased efficiency translates to fewer engine stages and parts, which reduces the engines’ weight and maintenance costs.

According to Pratt & Whitney, GTF engines’ reduced fuel burn rate cuts carbon dioxide emissions by more than 16%, and reduces regulated emissions by more than 50%. The engine builder said these factors would reduce CO2 emissions at a level equivalent to planting nearly 1 million trees every year. The engine also has reduces an aircraft’s noise footprint by over 75%, according to Pratt & Whitney.

The PurePower GTF has been selected as the exclusive engine to power the Bombardier CSeries, Mitsubishi Regional Jet, and Embraer's E-Jet E2 series of regional aircraft, and as an option by Airbus for the A320neo and Russia’s United Aircraft Corp. for the Irkut MC-21.

"The PurePower Geared Turbofan engine provides immense value to the future of sustainable aviation," stated Dr. Alan Epstein, Pratt & Whitney's vice president - Technology and Environment. "Its development spurred a new period of innovation among commercial aircraft manufacturers."