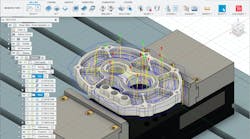

CLOUDNC – a CAD/CAM developer backed by Autodesk and Lockheed Martin – recently announced its CAM Assist solution is available as a plug-in for Autodesk's Fusion 360 software platform, allowing U.S. manufacturers to precision machine components more quickly and efficiently. CAM Assist uses advanced computer science techniques to generate professional machining strategies for three-axis parts in seconds, which could take CNC machine programmers hours or even days to manually create.

As a result, the amount of time it takes to program a CNC machine to make a component can be reduced by up to 80%, compared to the previous manual programming process, saving manufacturers hundreds of production hours a year.

CAM Assist is publicly available to download, via the Autodesk App Store.

“CAM Assist is the biggest paradigm shift for the precision manufacturing sector in decades, and by being available through the Autodesk App Store, machinists across the U.S. can now benefit. By making CAM programmers faster, CAM Assist enables manufacturers to increase machine uptime, slash lead times, improve process stability, and upskill staff to become expert machinists more quickly. These advances will re-energize precision manufacturing companies struggling with rising costs and aging workforces.”

Previously, depending on complexity, it could take a CAM programmer between an hour to several days to determine the best strategy to CNC machine a new component. This includes selecting the correct tools, strategies, and techniques - determining between hundreds of thousands of potential variables and approaches.

Instead, CAM Assist uses advanced computational optimization and AI inference techniques to rapidly determine a professional strategy and toolset needed to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library.

A Fusion 360 user can upload a 3D model of a 3-axis component and the software determines the best milling tools needed from those available, and how they will be used. In seconds, CAM Assist drafts the code required to instruct a CNC machine how to make it, within the user’s existing CAM platform.

At its core, CAM Assist is like a machining technician - it has a practical understanding of the physics and processes of cutting metal so it can make the sort of decisions that a machinist would make.

CloudNC has conducted side-by-side trials of CAM Assist with senior CAM programmers. According to the results, CAM Assist users can reduce programming times by up to 80% in comparison to manual programming methods, saving time for more senior programmers by completing tasks associated with program set-up and toolpath creation.

New users also can use CAM Assist to start to learn how to use software platforms like Fusion 360 far faster, producing components on the day of first use.

While the software today performs best with three-axis components, multi-axis, and freeform capability will be accessible to beta customers shortly.

Learn more at www.cloudnc.com