The Relationship Between Allowances for Detail and a Cutting Tool

When a tool designer develops cutting tools, he must understand some basic principles about the allowances for detail and the cutting tool design.

1. There is a ‘golden rule’ for cutting tools: the allowance for a cutting tools is always located inside the allowance for a hole or groove, and it s less than the allowance of holes, slots, or cutters.

2. Next, it is a very good practice to make a sketch of the locations of these two allowances, to see a correct image of the design, and to avoid mistakes.

3. Then, in order to use the full material of the cutting tool we must fix a maximum allowance for the cutting tool, which is less than the maximum allowance for the hole or groove.

4. Next, when the diameter of the cutting tool reaches a minimum of the cutting tool allowance we must take it out of the machining operation. All machining must be done under control.

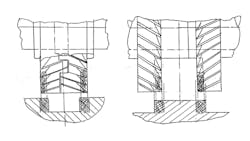

If your task is to machine a hole diameter that is

20+0.140 maximum and

20+0.000 mm minimum by counterbore,

the diameter of that counterbore will be 20.100+ 0.003 mm for the maximum diameter of the ready counterbore.

If, during machining, the counterbore gets to a diameter of 20.040 + 0.005 mm (minimum diameter), then we need to take it out of the machining operation.

Formula MLG – 3

M = A.H – A.T.

Where

- A.H. is the allowance for the hole

- A.T. is the allowance for the tool, and

- M is the difference between the allowances, which the tool designer will obtain from the technological standards.

When you machine long, precision slots or blocks with large numbers of details, it is more economical to us sets of plain disc cutting tools than to use one cylindrical milling cutter, because it does not have to be reserved for grinding.

For the design of a set for milling slots with two disc cutting mills, the tool designer must remember the Golden Rule about the relationship between the allowances of the slot and cutting tools.

If you are machining a slot

30+0.140 mm maximum

30.000 mm minimum

then, a set of two plain cutting mills will have

M.T = 30.120 +/-0002 mm maximum size

to start machining, using full material, and the size of the edges will have

30.040 +/-0.002 mm minimum size.

After this, proceed to the regrinding of the wear set.

For regrinding: between the cutting tools there is sometimes located a ring with good surface that contacts the cutting tools. After regrinding the wear from all cutting edges and making new edges we make a measuring set from edge to edge, and the result is

G.T. = 29.000 + 0.002 mm (for example),

meaning that the additional ring will be

G.R. = 30.120-29.000 = 1.120 +/-0.002 mm.

Formula MLG – 4

G.R. = M.T – G.T.

Where

- M.T. is the maximum size for cutting tools

- G.T. is the size of the grinding/regrinding tool set

- G.R. is the size of the new grinding ring.

When you machine blocks or long bons by sets of two plain cutting tools, the wear will work from the inside to the outside and a ring or bush must be ground to a smaller size.

When you machine a block

30.000 + 0.000 – 0.140, max. 30.00, min. 29.86 mm

you will need to place between the edges two cutting tools, sized

29.900 +/-0.002 mm

to start machining, and then sized

29.96 +/-0.002 mm

which then goes to regrinding.

If after regrinding the set has a new edge sized at 32.000 mm (for example), then we have a size of

32.000-29.90 = 2.100 +/-0.002 mm

Then we need to reduce the size of the ring or bush to

2.100 +/-0.002 mm (between the cutting tools.)

About the Author

Mark Grizotsky

Owner

Mark Grizotsky, owner of MLG Tool Design in Willowdale, Ontario, has been a major contributor and influencer to machinists everywhere with his insights to machine design and set-up, tooling design and selection, and advice for preparation and processes.