Swiss watchmakers have a reputation for precision and high quality that must be maintained, and linear guide rails developed by CNC machine-tool builder Almac are part of that effort. Those design elements help the watchmakers’ ultra-precise, 3- to 5-axis machining centers produce a better quality component.

Another factor in their effort maintaining their high standards is their use of Alphacam, one of the most popular CAM systems in Switzerland’s watch industry.

Almac director Roland Gutknecht claims his company is the only machine manufacturer using the technology of four linear guide rails fixed on a prism. “This enables us to give a high warranty of movement in the Z-axis. The four guide rails hold the spindle in perfect linear position, so there’s absolutely no tilting of the spindle. And, there’s no thermal displacement of the spindle, as the heat goes into the centre of the prism.”

Gutknecht said the machines guarantee very high stability and accuracy, which delivers the top quality machining the users require.

“The watchmakers who use Almac CU 1007 machining centers produce better quality components than their competitors who don’t have them,” he noted. The CU 1007 has X and Y slides on pre-stressed rails and a ball screw. A solid cast iron prism — on which a rectangular sleeve moves, guided by the linear rails and moved by a ball screw — forms the vertical axis.

As well as the watch industry, Almac machines are used to micro-machine parts needed in medical equipment, aeronautics systems, jewelry, and electronic component connectors.

With just under 50 employees at its factory in La Chaux-de-Fonds, Switzerland, Almac produces between 60 and 70 machining centers per year, with high accuracy in all three X-, Y- and Z-axes.

“Many of our customers, particularly leading names in the watchmaking industry, such as Roger Dubuis, Cartier, and Jaeger Lecoultre, work to extremely accurate detail, often as tight as five microns,” the director said. “They need their machines to be in almost constant production, day and night, so we supply the full package, including robots, loading and unloading stations, and peripheral equipment for cleaning and deburring.”

Just skimming the surface

In all cases where Almac produces components as part of the machine acceptance process, Gutknecht noted, they use Alphacam to generate the NC codes. And, when handling new orders they will receive details of a part for manufacturing trials in a STEP, IGES or dxf file, and create programs for the demonstration in Alphacam every time.

They also supply customers with special modules of Alphacam developed by the software’s Swiss reseller, MW Programmation, for a number of specialized functions. For instance, some watch decorations had to been done by hand before Almac designed CNC machine tools able to implement exclusive tasks for machining and decorating components that make up watch movements — and these machines are programmed with Alphacam. Almac also produces a range of specialty machines for manufacturing dials, cases, case attachments, and links.

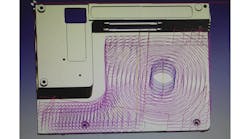

The macros for several of the special functions were originated by MW Programmation at Almac’s instigation, and now form part of MW’s industry-wide service across Switzerland. They include machining perlage (decorative details like circles, spirals and linear patterns); sequential numbering, to automatically generate serial numbers of pieces without needing to change the NC program manually; palpage, which defines exact placement of the piece before machining; and diamond settings, allowing parameters of the amount, size, and space between stones to be input.

Roland Gutknecht said perlage is a particularly important aspect of the programming: it’s the decorative motif often applied to the inside surfaces of watch plates and bridges, as well as on the dial side of the main plate. The cloudlike patterns are generated by the tool stipple the metal for only brief moments.

In addition to producing all their NC code with Alphacam for machine acceptance tests, Almac recommend the software as part of their package to start-up companies buying CU 1007 machining centers, and many existing customers already run Alphacam.

Macros, post processors, and more

MW Programmation works with Almac on every aspect of their customers’ Alphacam needs, including the macros, post processors, training and technical support. MW has two training rooms at its headquarters at Malleray, Switzerland, where they can tailor both basic and advanced courses to individual customers’ requirements.

Alphacam is one product from Vero Software. It’s CAM program applied for machining metal, wood, stone, or composite materials in 2-axis through 5-axis NC applications.

A recent addition to Alphacam’s functionality is a new Waveform 3D Roughing Strategy, which MW Programmation director Marcel Weber said will be of particular benefit to the watch industry. “The new high-speed machining technique maintains a constant tool cutting load by ensuring consistent tool engagement into the material. The tool moves in a smooth path to avoid sharp changes in direction, maintaining its velocity, dramatically decreasing the machining cycle time.”

He said the strategy is already popular with a number of his firm’s 1,000 clients across Switzerland, and is an improvement over traditional roughing cycle programming, where machinable geometry features are offset – inward or outward – by a stepover. Traditional tool paths have to run slower feeds and speeds because of the variable width-of-cut conditions encountered in corners. Tool loads spike as chip thickness increases in areas where the tool finds more material than it did while cutting in a straight line.

In order to ensure they remain a critical machine supplier to the Swiss watch market, Almac is training several apprentices with the skills to set the linear guide rails — a specialized task. “It takes a high degree of expertise to manufacture our CNC machines,” Roland Gutknecht said, “and an even higher degree of expertise to adjust the guide rails to the absolute level of precision required to ensure it is absolutely impossible to tilt the spindle.”