Performance and Flexibility Guide Design

Manufacturers’ expectations for precision and process control never remain static: for processes like turning and grinding, machine operators and developers are always looking for something faster, with tighter control over operations and results, and of course for finishes that are closer to perfect. Add to those objectives the growing interest in “flexibility”: the way that a machine or a program allows a designer or a manufacturer to adjust capabilities to the particular requirements of a product or an operation.

This is the context for much of the technological development ongoing in machine tool design and processing.

A ready example is the QXD250 grinding machine that the Vollmer Group will introduce to North America next month. It is the product of “many years of research,” Vollmer explained, prompted by customers’ inquiries and experiences with earlier generations of the QXD series.

“The highlight is the new Vpulse erosion generator,” according to Vollmer, “which can finish PCD materials 30% faster than any of its predecessors, and is also capable of achieving finishes as smooth as 0.1μ Ra. The modular automation, six axes CNC controlled movement as well as the ability to grind, erode and polish in one machine setup create an optimized solution for PCD tool processing.”

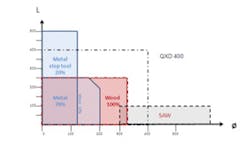

The Vollmer Group introduced its QXD400 rotary erosion machine for finishing polycrystalline diamond (PCD) tools in 2005. It was the first model in the QXD series, with six CNC-controlled axes moving simultaneously to machine the required tool geometries.

In addition, it incorporated a six-position holder for electrodes and/or grinding wheels, coupled with the automated tool magazine, allowed operators to machine materials unattended — boosting operating efficiency.

The QXD400 was built atop a unitary, 17,000-lb pound concrete polymer base in order to ensure high accuracy in all movements. That design was capable of completing tools up to 400 mm in diameter, with cutting lengths to 400 mm too.

In Figure 1, it is easy to see how the QXD400 could address many of the dimensional concerns for toolmakers producing PCD saw blades and metalworking tools, and all PCD woodworking tools. It complemented other Vollmer machine models, such as the QWD, QM, and QR/QF machines, in particular for finishing larger saw blades and the longer PCD metalworking tools.

Accuracy in a Smaller Footprint

With the advent of the QXD400 machine, many of companies producing tools for metalworking operations requested something with comparable high accuracy but with a smaller footprint, that could execute complete processing of PCD drills and end mills, too. This would have to include grinding of helical flutes and polishing the diamond surface.

Those requests were addressed with the introduction of the QXD200, in 2008. In order to maintain the design advantages of the concrete polymer base, and yet to achieve a smaller footprint, the axes were rotated 90°; in this way, all machining was performed with the tool in a vertical rather than horizontal position.

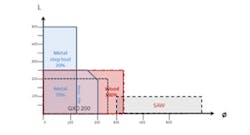

Recognizing that the largest diameter tool used in these applications is 250 mm, the QXD200 was developed with that dimension in mind. The vertical placement of the tool resulted in some limitations with respect to length, so that 200 mm became the limit for the tools as shown Figure 2.

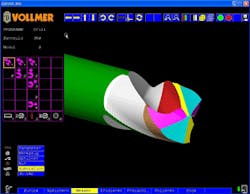

With the intention that this new machine also would complement the preceding models in the series, the QXD200 was introduced with the “revolutionary” ExLevel software that allowed tool designers to create 3D models of helical tools that could be finished in one machine setup. This software also allows designers to export the 3D model to the customer or toolmaker, for simulation within their own CAM software, as well as to verify any design changes prior to starting production.

The automation systems for the QXD200 were introduced as modular components that could be added to the base machine at any time. These devices are capable of holding up to 64 individual PCD tools in pallets that can be tracked using RFID. A smaller pallet system, the ND260, can hold up to 29 tools.

Approximately every six months after the introduction of the QXD200, Vollmer released additional functions, for example, the ability to erode radiused milling cutters used for processing glass lenses. It also introduced new software and hardware to produce high shear cutters with angles greater than 45°, as well as increased grinding capabilities for fluting and gashing.

The modular automation on the QXD200 was very well accepted by manufacturers. For them, it provided greater flexibility than past machining systems. Machine shops also appreciated the machine’s smaller footprint, as the availability of workspace grew more significant in operations seeking to expand their customer service by adding more process capabilities.

The QXD200 had some limitations though, in terms of cutting length for producing metalworking tools, and cutting diameter for producing woodworking tools.

Designing Past Limitations

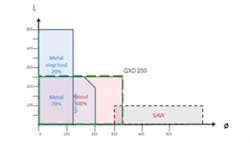

Researchers at Vollmer took those limitations as the starting point for the design of the new QXD250. Maintaining all of the critical components established first with the QXD200, the QXD250 was re-engineered to accommodate tools up to 320 mm in diameter, in lengths to 250 mm.

The automation concept was enhanced to allow processing of tools with weights of 25 kg or less.

“Even as important as these changes are to the customers and the various industries, perhaps the most significant change involved the erosion generator,” Vollmer noted. The new Vpulse generator is capable of removing material 30% faster than the QXD200, and achieves finishes of 0.2μ Ra.

In addition to its polishing capabilities, the QXD250 is able to erode PCD to finishes in the range 0f 0.1μ Ra with further processing.

As illustrated in Figure 3, the design resulting from these advances provides tool designers and operators with an optimal solution for toolmaking, with the widest range of dimensional capabilities for finishing an assortment of PCD tools.