Modular Tombstones Optimize HMC Flexibility

Producing a wide selection of fluid-power cylinders and related products for hundreds of customers, TRD Manufacturing Inc. was feeling challenged by an increasing variety of sizes, styles, and materials in their workpiece blocks.

“TRD is a fast-paced manufacturer,” v.p.-Operations Kerry Reinhardt explained, “but very dedicated to high quality and fast turnaround on deliveries. We have an established reputation as a solution provider to the fluid power industry.”

The Machesney Park, Ill., machining operations is a division of Bimba, a manufacturer of actuation devices. TRD sells its products through distributors to end users in the general manufacturing, automation integration, mining, forestry, medical, food and various mill industries. Its products are regularly specified as OEM components too, but TRD also serves a huge MRO marketplace.

Addressing an expanding product line was complicated by a commitment to just-in-time delivery. “TRD was seeking a partner that could develop fixturing to fit our manufacturing business model of quick set-up, and the flexibility to run small or large batches of product from a multitude of block sizes,” according to manufacturing manager Tom Jensen.

The manufacturer took its dilemma to a nearby supplier of various machine tool components, Advanced Machine & Engineering (AME) in Rockford, Ill. “After a few discussions and visits to each others’ plants, we knew TRD would benefit most from our Triag line of modular workholding devices,” the head of the AME workholding group, Alvin Goellner, observed.

Tom Jensen concurred. “We knew AME had a reputation for building top-quality fixturing,” he said. “Their in-house manufacturing capabilities were very impressive and we knew they could handle a project of this size, based on the other customers they serve and the fact that they are just across town from us, which made it easier to work through the preliminary discussions, quoting and final product delivery.”

Building Top-Quality Fixtures

For this production application, TRD uses an Enshu GE480H horizontal machining center with 30x30x30-in. travel and a 180-position tool-changer, expandable to 240 positions. Workpieces are mounted and handled on a Fastems 10-station pallet changer.

Currently, TRD runs 56 block sizes, from 1x2x2 in. to 3x9.5x14 in. Weights range up to 114 lbs.

Final part varieties produced on the machine number over 450, made from 1018 steel and 303 stainless. Lot sizes vary, from one-offs up to 500, but generally averaging between 25 and 50. This machining center set-up runs two shifts per day, with the expectation of running 24/7 during peak demand periods.

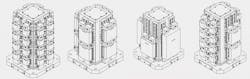

The challenge for Alvin Goellner and his team at AME was to design a series of fixtures flexible enough to hold 56 different block sizes, to offer quick changeover, and to establish an ability to run different parts on each side or run multiple pallet loads of the same part in high production, when needed.

“It was a real one-size-really-can-fit-all situation,” Goellner noted, smiling. “We knew the HMC with pallet changer was very costly to run, so keeping downtime to a minimum was essential.”

The solution came in the form of 10 Triag custom-modular tombstone-style fixtures from AME. Triag is a Swiss workholding component supplier, and AME is its exclusive North American distributor.

“The fixturing in our existing machining cell was fixed, based on block size,” Jensen noted. “AME fixtures use a vise system that quickly adjusts to any size with repeatability, a really key factor in the equation, as it allows all our work shifts to be pre-taught the process. We normally have the fixtures set for specific part sizes but this AME solution now allows us to run any size part on any pallet very quickly for high-volume jobs.”

He observed there was a very short start-up time in the TRD shop, as the flexibility of the tombstone design and the fixturing mechanisms were relatively easy to learn for the operators.

“We met with Alvin Goellner and brainstormed the improvements needed on our current fixturing system,” Jensen continued. “AME laid out a concept and provided drawings for each fixture, which we then reviewed and approved, based on our current production schedules and anticipated workloads, going forward. All the fixtures ordered arrived on-time or ahead of schedule, a very refreshing experience.”

Goellner was the lead man for AME on the project, bringing his 20+ years of fixture design and build experience to the task. Because all aspects of this project’s customized manufacturing, assembly and test of the Triag tombstone fixures were done in-house at AME, there was little delay in the processing of the project and all design changes were quickly accommodated, according to Jensen.

“The overall experience was excellent and the results have been outstanding for TRD. The project went well and all our expectations were met,” Reinhardt commented. He estimated the improvement percentage in production on the Enshu HMC to be over 40%, after several months in operation.