The global automotive industry appears to have passed its crisis point, noted EMAG Maschinenfabrik GmbH, observing that there are a number of production challenges remaining for the OEMs and their Tier suppliers. Specifically, the builder of pointed machine tools identified the need for “sub-contractors” to respond to the rising levels of automotive output, and to ensure that production process safety standards and component quality are not impacted adversely once production rates rise.

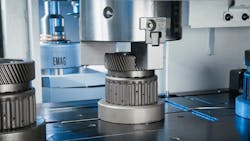

“In fact, even the smallest components with complex geometries must be produced with increasing levels of precision,” EMAG explained as it introduced its VLC 100 G vertical grinding center, based on a “machine concept (that) offers efficient, error-free machining processes for the production of small chucked components.”

Typically, small chucked components are produced in high volumes, and automotive demand for components like gearwheels, planetary gears, chain gears, and flanged components involve quantities in the millions. Also, the cycle times for producing these parts are increasingly shorter. EMAG described how the internal contour of a gearwheel must be ground as quickly as possible, and the machine’s workholding unit reloaded with a new workpiece just as quickly, so the rate of production can be met. “In many production environments, this represents a critical moment, because the idle time is commonly a decisive factor in establishing the economic viability of the whole process,” it detailed.

High output levels and short cycle times for small chucked components (maximum diameter 100 mm) were EMAG’s primary objectives in the design of the VLC 100 G vertical grinding center. The machine uses an onboard pick-up system to load itself, and while one workpiece is being machined the operator – or the automation system – is placing new workpieces on the conveyor belt. This reduces idle time and increases output rates. Another advantages is the vertical machining concept: the design ensures that the grinding sludge falls to the bottom of the machine, and then evacuated.

Measuring processes can be integrated into the machine, making quality control integral to the production process. The measuring probe is located between the machining area and pick-up station, where it is protected from contamination.

Two grinding spindles

An important design element of the VLC 100 G is the inclusion of two grinding spindles, which can perform different grinding operations, or handle both roughing and finish-grinding. The first wheel removes excess material from the blank workpiece at high feedrates (the CBN wheel is specially designed to absorb the necessary force), while the second wheel (with different specs) takes on the more difficult finishing work, even for difficult geometries. This “intelligent tooling combination,” EMAG noted, reduces considerably the grinding time for complex parts.

“For the removal of large amounts, two wheels offer a shorter cycle time than one, with the first wheel designed to do the rough-grinding and the second one in charge of finish-grinding work,” stated Dr. Guido Hegener, EMAG managing director.

The combination of fast loading and efficient grinding processes leads to a very compelling machine concept, according to the builder. The VLC 100 G works well with the emerging demands of automotive design and production. With the rising demand for higher volumes, there is a need for new machine concepts that can be integrated into existing production without any problem, EMAG indicated.

The VLC 100 G has two features that allow it to be integrated smoothly to machining operations. “Programming the workpieces with our new EMAG Navigator software is simple and intuitive, saving valuable setup time. For many production environments, this is an advantage that should not be underrated,“ according to Dr. Hegener.

Also, the small footprint for the VLC 100 G should make production planning easier. The stand-alone machine occupies about 4.5 square meters (48 square feet), ensuring that the growth of a production facility of this kind will not be limited by floor space requirements.

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.