Two compact machines, designed in a mirror image of each other, hard-finish automotive transmission gears. Developed by the KAPP Group, one machine grinds, while the other handles the Coroning, which is KAPP's trademark honing process that uses a single-layer diamond-plated tool instead of vitrified stone. The machines can run independently or together.

Putting a grinder in front of a honing machine controls the quality and stock conditions of gears entering the honing machine. It further ensures a balanced system with minimum total-processing time and high-quality gears. "This is the first time a manufacturer has designed two machines in a mirror image of each other to work in an automated system," says Tom Lang, vice president and general manager of KAPP Technologies.

The two machines are the KX300P and the CX250. The KX300P is the latest model in the company's external-generating grinding machines. It is capable of dressing vitrified worms and form wheels, but can also use CBN-plated worms and CBN-plated form wheels. In addition, it features on-board inspection and integrated balancing. The CX250 is a Coroning machine that incorporates single-layer plated-diamond-coated Coroning rings, for short machine-setup time. To keep the Coroning extremely stable, there is no dressing in the process. The CX250 has the same control system, electrical system, and software and HMIs (human machine interface) as the KX300P. With identical controls and HMIs, one operator handles both the setup and operation. It also simplifies training.

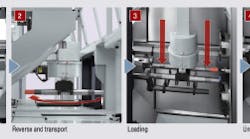

To enhance automation, the machines are positioned face-to-face, and one gantry services both machines with a conveyor band running between them. Furthermore, one coolant system services both machines. "This can save users more than $1 million in upfront expenses for medium-sized installations and hundreds of dollars in additional oil costs since only one type of oil is needed," adds Lang.