Tooling requirements change when tool diameter is decreased and spindle speed is increased.

The differing characteristics of workpiece materials, copper, aluminum, steel grades, and exotic materials such as titanium, graphite and composites, require that tool geometries and tool coatings be material-specific.

And because of the tiny scale of micromachining, solid carbide rather than steel is the choice for micro tools. The choice of solid carbide provides the twin benefits of production efficiency and a high return on tooling investment.The three components of a cutting tool — geometry, coating and substrate — define the correct tool for given applications, but ways those components go together, and the importance of each, vary from one material to another.

Run small, run fast Smaller tools require higher spindle speeds to efficiently machine quality parts and to avoid tool breakage.

High-frequency spindles with speed ranges to 60,000 rpm are ideal for milling, drilling, thread milling and engraving using micro tools.

High-speed machining technology uses high tool-rotation rates, taking a small stepover, but with significantly increased feedrates. The principle behind high-speed machining is that there is insufficient time for heat to feed back into the part and cause problems.

During the machining process, the tool continually carves a chip out of the work piece. The generated heat develops approximately 40 percent from friction on each side of the tool and 20 percent from the deformation (bending) of the chip. Therefore, about 60 percent of the heat is inside the chip. High-speed machining techniques evacuate the bulk of the heat with the chip, providing for a cleaner cut. The improved machining quality is based on cooler tooling, lower machining forces, and therefore less vibration.

High spindle speeds reduce the chip load to less than 0.005 in. A chip load that low significantly lowers the forces between the tool and the material. High-speed/low-force machining yields less heat, reduces tool deflection, and allows machining of workpieces with thinner walls.

This all results in cooler machining, superior surface and edge quality, better accuracy and, as a by-product of the low force that is used, easier workholding. In many jobs, modular vacuum tables can be used for quick set up and job changeover, especially with thin flat substrates.

Tool geometries Efficient machining with small tools requires the tools to be optimized for high-speed machining applications. The proper geometry of micro tooling, together with the right high-speed spindle and the ideal coolant, can eliminate deburring and degreasing as secondary operations.

Because of the high speeds, chip removal is a major concern when micro machining, Walter Schnecker, president of Datron Dynamics (www.datrondynamics.com), said.

Scaling down the geometry of larger-diameter tools to a smaller format does not provide adequate room for chip removal, and yields unacceptable feedrates and unsatisfactory finishes.

Conventional tooling that uses inserts is not appropriate for micro-tooling applications primarily because of the high rotational speeds used. Contrary to common wisdom, the tool diameter does not have a significant role in the use of inserts in these applications.

Increased speeds require properly balanced tools that have significantly increased chip room to ensure proper chip removal, and to prevent chip burn up.

Tools used to machine hard materials, such as tool steels to 65 HRc and cobalt chrome, require less chip clearance than those that are used to machine softer materials, resulting in larger tool core diameters that increase rigidity and strength. Protection of the cutting edge is also critical and is accomplished by minimizing rake angles and applying specific edge preps and hones.

Softer materials, such as aluminum, copper and plastics, require freer cutting geometries with increased chip clearance. Tools that have increased rake angles are used for these materials to maintain a sharp cutting edge that maximizes shear action.

Single-flute tools are designed for machining soft materials such as aluminum, copper and plastics. This design allows increased chip clearance and the ability to generate sharper cutting edges to reduce cutting forces while increasing shear. Two-flute, or multi-flute, micro tools typically are used in all other applications to maximize core diameter and tool strength.

The harder the material being cut, the lower the flute helix angle should be.

Helix angle is the angle formed by the flute and the cutter-body centerline.

Because most of the heat developed when cutting hard materials is in the chip, a low helix angle removes the chip quickly, before heat has a chance to enter the tool.

Stephan Jean, milling products manager a t Emuge Corp. (www.emuge.com), said his company offers hard-material milling cutters that have zero-degree helix angles.

Tools with higher helix angles are used for cutting softer materials because they peel away the material that is being cut more quickly and prevent chips from adhering to the tool.

Seco Tools Inc. (www.secotools.com) has found that the design of the tool neck is critical to increased stability and strength.

Rob Keenan, manager of sales and marketing for Jabro products at Seco, explained the two features of this design.

“First, there is the transition radius where the O.D. reduction blends into the shank. Then, there is the taper on the O.D. reduction of select tools."

“We have found that the transition radius from O.D. reduction to shank plays a vital role in tool stability and strength. By optimizing this radius we have tripled tool life,” Keenan said.

“Adding strength to the tool also reduces deflection to improve tool life, surface finish and overall part accuracy. In the past, very few micro tools ever wore out, they usually broke due to excessive tool pressure and deflection. Now, we can get full life out of micro tools. When part geometry allows, we use a 0.9-degree taper on the O.D. reduction, further improving strength and rigidity,” Keenan added.

Emuge Corp. also has investigated the effect of tool neck geometry.

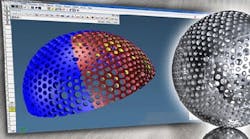

Through finite-element modeling (FEM) techniques, the company found that the largest possible tool web diameter is not necessarily the most stable. The company’s studies indicate that an optimum ratio of neck diameter (smaller than the tool cutting diameter) to cutting diameter results in minimum tool deformation.

Tools that have this design have a necked-down, parabolic-shape rather than a constant transition angle from tool diameter to shank diameter.

For example, a tool with a 0.5-mm cutting diameter and a 0.4-mm minimum neck diameter was most stable. Similarly, a tool with a 1.0-mm cutting diameter was most stable with a minimum neck diameter of 0.8 mm. With this configuration, stresses in a micro-tool neck were reduced by about one-third, as predicted by finite-element modeling analyses.

Also, with micro tools, it’s best to keep tool length to a minimum.

The shorter the cutting length, the more stable the tool. And, the more stable the tool, the faster it can be run. Also, a short cutting length typically produces better surface finishes.

Tool flex leads to vibration, runout and poor finish quality. Unstable tools require increased energy to make each part, since some of the energy is translated into unproductive tool movement instead of cutting force. These unproductive forces also shorten tool life, leading to increased frequency of tool replacement and additional tooling purchases. Over time, this translates into additional machine stress and maintenance requirements.

Some shops prefer HSK-style toolholders for microtools because they shorten the distance from the toolholder to the cutting zone, and increase tool stiffness while minimizing tool deflection.

Substrates and coatings

Carbide substrates for micro tooling typically have a grain size of 0.5 microns or less. This allows sharper cutting edges to be ground on even the smallest cutting tools. A better surface finish on the cutting edge translates to better surface finishes on the part, improved part quality and longer tool life.

However, the small grain size makes the carbide more brittle, so for success, runout and vibration must be minimal and clamping must be rigid.

Coatings serve several important purposes depending on materials to be machined. Coatings

- Reduce friction.

- Increase lubricity.

- Provide thermal protection for the cutting edge.

- And, add wear resistance.

Hard materials, such as tool steels and cobalt chrome, require coatings designed to form a thermal barrier to protect the cutting edge and to minimize friction to reduce cutting forces. Specific formulations of AlTiN coatings work well with these materials.

Softer materials, such as aluminum and copper, generate less heat, but chip loading or built-up edge become issues with these materials.

Tool coatings that are designed for these materials have increased lubricity to allow a smooth flow of chips. Some manufacturers also polish rakes and flutes to enhance chip flow.

Abrasive materials, including graphite, carbon composites and other non-metallic composites, require extreme wear resistance for satisfactory tool life. Seco Tools reported its CVD diamond coating on Jabro Mini tools improves tool life by as much as 20 times in these materials.

Coolants Coolants are used in machining to reduce friction, avoid adhesion of chips to the cutting tool, reduce the temperature at the cutting edge and improve chip evacuation and removal.

The most appropriate of the three basic types of coolants used in micro machining depends on the application and material to be cut.

- Emulsions – Typical water-based flood coolant used for machining aluminum, copper, titanium and stainless steels. This type of coolant is not recommended for hardened tool steels because it can thermally shock carbide and cause micro cracks at the cutting edge.

- Oil Mists – Vegetable-based oil combined with air to form a very light mist. This type of coolant is used primarily to lubricate — not to cool — the tool. This coolant is the recommended type for hard tool steels.

- Air blast – Used for chip evacuation and in jobs for which oil mist is unsuitable or not available.

A small tool that has an intricate geometry and is turning at an extremely high speed may require a cooling and lubricating agent that has viscosity lower than water.

Some micro-volume coolant spray systems can use ethanol, an alcohol that occurs naturally in the sugar fermentation process. Ethanol has a viscosity lower than water, and its low-evaporation point makes it an efficient cooling and lubricating agent for high-speed machining operations. In addition, where conventional flood coolant is petroleum based and needs to be disposed of properly, ethanol evaporates. That evaporation eliminates costs associated with disposal.

In addition, ethanol as a coolant evaporates cleanly and does not leave a residue on machined parts, so it eliminates costly secondary degreasing operations. Ethanol is best for machining aluminum and sometimes can be used with copper and brass.

Because it is flammable, ethanol should be used only to machine nonferrous materials and not to machine steel-based materials. Also, steel parts that might create sparks must be kept out of the cutting envelope. Machines that have automatic fire-extinguishing systems are a good idea and a must for unattended operation when ethanol is used as a coolant.

| Hard machining musts The basic tool-geometry requirements for machining hard materials are:

Optimal cutting parameters and machining strategies are critical for success. |