Coolant Wizard Inc.; founded 1995

Computer technology kicked off the 1980s and continuing advances in hardware and software kept things running strong through the 1990s. But it was byproducts of computers that really launched change in the last decade of the century. The World Wide Web or Internet, released by CERN in 1991, opened up the possibility for floods of information to reach PC users — pushing the "information age" to new extremes. By 1997, 19 million users, and potential consumers, were accessing information about almost anything. Because of the net, computers from remote, and even not so remote, locations had a new way of networking together. Windows became the standard platform for all programs, and there was a new consumer interest for open architecture on machine controls so that different brands and types of software could communicate and work together. The Internet also redefined the flow of information to customers who could anonymously access company and product information to shop or purchase on-line. E-commerce was now something every company had to consider, and "dot-com" companies and B2B marketplaces started dominating on-line purchasing.

Advances in computer hardware, software, and communication helped bring the manufacturing market into its current state. And the increasing economic prosperity along with technological innovations in the 1990s inspired many entrepreneurs to start their own companies.

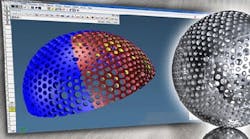

Integration, information access, and clear communication between manufacturing system software is still much sought after by machine tool companies. "Open architecture" became the new buzz word in the 1990s, and companies began to actively seek ways to keep the communication open between different systems. When Charles S. Hutchins, Bruce E. Nourse, James R. Fall started their business, they wanted to help companies control their manufacturing assets by providing them with real-time information. The founders' original intent was to develop software for real-time data collection from a machine tool. But they soon discovered that CNC controls were so tightly closed and restrictive that it was impossible to gain access to the machine data. What they needed was an open-architecture, all-software, non-proprietary CNC, so they created one.

Manufacturing Data Systems Inc. was formally launched in 1995 and sells CNC software packages marketed exclusively as software. OpenCNC is a patented, real-time data-collection technology serving as a foundation for B2B e-commerce and Internet-enabled manufacturing. OpenCNC lets high-end, multi-axis machine tools be controlled entirely from unbundled software without any motion control cards, proprietary hardware, or embedded firmware.

Not all software developments came about to improve the workings of CNC. Lilly Software Associates Inc. was launched in 1992 by Richard T. Lilly to develop software for enterprise resource planning, advanced planning and scheduling, warehouse management, customerrelationship management, quality management, and e-business. Lilly's business goal was to create a Windows-based manufacturing software solution for the jobshop, make-to-order segment. "My goal was to have one screen, or perhaps a small set of screens, that was so contextually rich with meaning to the user that anyone could sit down and easily learn the system just by looking at the main manufacturing system window," says Lilly. Lilly had trouble convincing some people that his user-friendly interface was worth the cost. He had gotten word that a small job shop up the road in Portsmouth, N.H., was interested in an inventory package. He made an appointment with the manager of MIS, but it wasn't long into their meeting before Lilly was thrown out of the office. "He was outraged, it seemed, that I had priced a 10-user system, at $40,000. There was nothing I could show him that would justify in his mind spending more than $3,000. A couple of days later, the vice president of finance called. He'd gotten word of what I'd started to lay out to the MIS manager before being dismissed, and he was curious. In the early part of December, we signed our first software license agreement." Shop management was also the niche market that Billie and Rich Henning decided to tackle when they started Henning Industrial Software Inc. in 1990. The couple got inspired to write management software for the company Billie worked for at the time. The small shop couldn't affordably purchase anything off-the-shelf to meet its needs. With this in mind, the Hennings began writing a marketable estimating and shop-management solution for small-to-medium shops. Today Henning makes EstiTrack shop management software with extensive drag-and-drop scheduling techniques for fast and easy processing. The company also offers Visual Books accounting software and Visual Web Track for web-based customer service.

Business in the 1990s was not only changing technologically, but philosophically. One new idea being embraced was "value-added service," which emerged as the new standard in client relations. Companies expanded service departments, built new service centers, and some even incorporated training programs to help customers learn to use new equipment. This was also a time when manufacturing sales teams started consulting instead of just selling, and firms bent over backwards to develop more customized/specialized approaches to meeting clients' needs. With this change in focus, new companies found opportunities to meet service needs of customers being ignored or lost in smaller markets.

Michael Weiner, for example, saw a demand in the tooling market that wasn't being met, so he started Tool Coating Services Inc. The company started making Chemical Vapor Deposition (CVD) and Physical Vapor Deposition (PVD) coatings in 1995 because, at the time, there were few coating services providing CVD coatings on a toll basis. Also, the equipment many companies used was outdated and incapable of producing a quality aluminum oxide coating.

When Toshiba Tungaloy Manufacturing decided to close its U.S. manufacturing operation, Weiner seized the opportunity and purchased its CVD coating furnaces so he could offer a high-quality aluminum oxide coating on a toll basis.

The company introduced a thin-film CVD coating (3 mm) to work on sharp edged tooling and thick-film coating (14 mm) to extend useful life in turning applications. It also now offers PVD coatings.

Richard Ward also spotted a good opportunity in the service industry. He noticed that one disadvantage of doing business in the information age was that vast quantities of new technology can, at first, seem more confusing then helpful. That's why he started Richel Inc. in 1995, a waterjet cutting consultant firm and dealership. He wanted to help existing waterjet operators understand their systems better. Ward believed so much in his new business, he sold his car to finance it and drew no salary from the business for the first six months. The company has customized software specifically for waterjets and sells a ball-bearing tank to reduce setup time for complex parts. Ward is also the sole distributor of a waterjet abrasive recycling system from EasiJet.

The 1990s also spawned a new market for service-oriented companies that wanted to help manufacturers meet the increasing regulatory demands passed regarding safety, environmental, and quality issues. Meeting OSHA standards became more challenging in the 1990s and passing ISO standards became mandatory fare for manufacturers.

This opened the door for many new companies that could act as consultants or that could produce products to help companies meet the new safety and quality demands. Coolant Wizard Inc., started in 1995, was one company able to service these growing needs with innovation. William Bettag was a coolant salesman who was being confronted by customers wanting to save coolant costs through better fluid management. These customers wanted him to find a way to make coolant last longer and not smell, while also removing tramp oil that was causing excess smoke.

Bettag developed a questionnaire in 1991 and approached a large number of his customers. Bettag says, "They essentially told me how to build the equipment and what it needed to do."

That's how the company started its current line of water-misable metalworking fluid reconditioners. But making an attractive, marketable product was not always easy. After the initial concept was developed and marketed, sales were, as Bettag puts it, "slow at best." He knew he needed a more marketable design for the product. This became apparent when a prospect was taken to a shop where the system was in use. After seeing what the system was capable of, he said, "I have no doubt that it works. I will not own one because it looks like something a farmer built over the weekend with what he could find in a barn."

Improvements were made and now the company is doing well and selling a polished product with proven results.

As with all the decades in the 20th century, what begins in one decade paves the way for progress in the years that follow. Most of the new technology being displayed at IMTS 2000 got its start in research labs and marketing meetings in the 1990s. That's the case for PCC Olofsson and its new line of year 2000 machine tools. That company's new multitasking machine tool can handle turning, boring, drilling, and milling operations and can be customized for 30 different configurations.

The 1990s started many of the trends now coming to fruition in the 21st century. For instance, the 1990s was the decade when manufacturers first added linear motors to machine tools, started making machines with multitasking capabilities, and began dry machining at high speeds.

Attendees at this year's IMTS can take note of all the latest developments and know that those innovations are paving the way for radical changes that will influence the industry for decades to come. It's hard to imagine the future of machine tools and the metalworking sector, but it's inspiring to look back on the last century, see the amazing pace of change, and imagine how far the industry will go in the next 100 years.

Companies founded in the 1990sHenning Industrial Software Inc. (1990,) Lilly Software Associates Inc. (1992), Cryoplus Inc. (1994), Open Mind Software Technologies (1994), Coolant Wizard Inc. (1995), Manufacturing Data Systems Inc. (MDSI) (1995), Richel Inc. (1995) Toll Coating Services Inc. (1995) |

James Fall, Charles Hutchins, Bruce Nourse Manufacturing Data Systems Inc. (MDSI)

1990

These three men originally got together to develop software for real-time data collection and discovered that the industry needed an open-architecture, all-software, non-proprietary CNC. So they began production of the first unbundled CNC on the market that was packaged and marketed exclusively as software. MDSI has shown that complex CNC machine tools can be controlled from unbundled software without motion control cards, proprietary hardware, or embedded firmware. MDSI's software, OpenCNC, lets manufacturers download real-time machine data from remote locations and run machine tools from the internet. The company recently won the Vision award from Microsoft and Start Magazine for transforming the manufacturing industry through the use of Microsoft technology.