One of the critical measurements of machine shop productivity has always been equipment uptime, and improvements in recent years mean that result may mean a difference of just a few minutes or even seconds. In large-volume machining operations making long runs of metal or composite parts, the time involved in tool changes alone can add up to hundreds of thousands of dollars annually.

The introduction of the Sandvik Coromant Capto® quick-change tooling system in the 1990s resulted in up to a 25 percent increase in productivity. More modern tooling now takes those gains and reduces change time even further, taking tooling changes from minutes down to seconds.

“One of the major factors behind our decision to incorporate the quick-change system is our goal of improving setup time,” explained Jimmy Lytle, president of Daystar Machining Technologies Inc., a Fletcher, N.C., job shop with state-of-the-art CNC turning and milling centers. The shop focuses on precision machining and fabrication with quick turnaround for short-run, prototype, and specialty-part production.

“Now, our setup time has been reduced from minutes to seconds,” Lytle continued.

Faster Changes, Better Tooling Life

Making quick tool changes and improving tooling life continues to be a priority for production machining operations and job shops everywhere. Not only are the savings in setup and changeover time increasingly valuable to them, but the flexibility and stability of the quick-change system also are important -- as is the potential for reduced capital investments in tooling.

A new and noteworthy development is the introduction of Solidfix, a versatile, modular quick-change collet system that helps machine operators to perform setups and changeovers in 15 seconds or less.

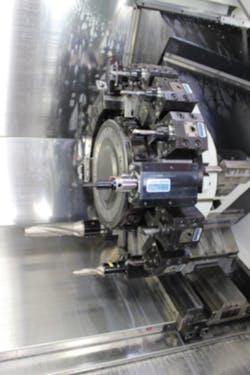

Daystar installed the Solidfix system recently on two new lathes, live tooling Y-axis machines. “We have quick-change adapters on all the live tooling for those lathes,” Lytle said. “We can set the adapters out on the work bench and get everything ready for a setup. Then we are in and out of the machine very quickly.”

The adapters Lytle described are a central advantage of the Solidfix quick-change system. Adapters are attached to individual tools and are inserted quickly and easily into a head via a bayonet-type mount that is then secured simply by turning a single nut using an Allen wrench. Various popular soft tools, such as live turrets, angle heads and static tools, can be interchanged with different size adapters. The system will fit older machining equipment as well as newer models.

Developed and manufactured by Benz Inc., this modular quick-change system saves operations like Daystar several minutes of time for each setup, and also reduces their investment in tooling.

When a shop finishes a run with conventional it must take out the driven tools, remove and clean the collet – a relatively unwieldy operation, requiring the use of two hands and multiple tools – and then install the new tooling, and take offset measurements. All of that can easily take two or three minutes.

Using the Solidfix system, operators don’t have to remove the main tooling unit itself; they simply change the adapter, which holds the pre-measured tool. This also means that the operator doesn’t have to buy as many live tools, which are expensive by themselves. All they have to buy are the quick-change adapters.

“We are able to switch from a collet chuck to a shell mill adapter to a solid end-mill holder without having to change to a different live tool holder for every application,” Lytle explained. “Using this quick-change system, we have one, somewhat expensive tool holder and everything else is fairly inexpensive, which gives us a great deal of versatility without a major capital investment.”

Large and small shops are able to se the Solidfix system to reduce the number of live tools or angle heads as the spindles can be changed from ER collet to mill arbor adapter, Weldon or whistle notch adapter, shrink fit, and various special tooling.

More Plug-and-Playable

In the development of its new modular system, Benz took the original quick-change technology and simplified it. Instead of requiring operators to spin on and tighten tooling in the holder using a wrench, the new system requires only a simple turn of an Allen wrench.

Also, in a traditional quick-change system the operator has to remove the tool and install a new tool. Then, he or she must touch-off their tool to ensure the offset is correct. With the Solidfix, the operator can preset tools on a granite surface plate. When the tool starts wearing or another type is required, he or she simply inserts and secures the new tool.

“Essentially, they’re putting the whole tool aggregate back in, and the repeatability is so accurate that they can program-in what they just measured off their height gauge so they don’t have to go through that scenario of touching-off the tool, and then programming the offset,” according to Mike Starnes, Benz sales application engineer. “So, Solidfix is really a plug-and-play system. Operators just switch out the soft tooling, and they’re all set.”

When operators try to work quickly on a traditional setup, they can be exposed to injury. Starnes explained: “Normally, the cutting tool they are removing is very sharp. Even if it’s too dull to machine a part accurately, it’s still very sharp to the human skin. If the operator gets cut while handling one of those tools, the wound could be deep enough to require stitches. So, even highly experienced operators have to be very careful when handling cutting tools. When these mishaps occur, they have to go the nursing station and at least get the wound cleaned up. In more serious cases, they may have to go offsite, to a doctor or even the hospital. Of course, when such injuries occur, even more production time may be lost.”

Starnes added that with the Solidfix system, operators are performing a much simpler task, which in most cases can be performed using one hand. Because of the ease of mounting and securing the adapter and tooling, exposure to potential injuries – and loss of operator time - is minimized.