Most machine shops will evaluate new cutting tools in an effort to reduce machining time, increase tool life, or improve part quality, and sometimes to accomplish all of this. But, Stellar Precision Components Ltd., a Tier 2 aerospace supplier in Jeanette, Penn., did it for an entirely different reason. “We’d just taken an order for some Inconel parts,” recalled production manager Edward Frieze. “None of us were really worried at that point about tool life or making a profit on the job; our only concern then was how the heck could we get them shipped in eight weeks.”

Opening doors — Four decades ago, Mike Vucish was working for a manufacturer of naval nuclear components when he saw an opportunity to start his own business. He bought some machining equipment, invited a few students from the technical school where he taught a shop class at night, and opened the doors of Stellar Precision in 1978. Vucish continued to work at his day job until his start-up was more established, but in the meantime he brought some family members on board to help.

“We started out doing a lot of overload work from other larger shops in the area, but that evolved into direct support of several nuclear programs because of my father’s experience,” said Vucish’s daughter Lori Albright, now the owner and president of Stellar Precision. “We’ve since become a key supplier to a number of prime aerospace and defense contractors, including Boeing, Lockheed, and Raytheon, as well as various nuclear and medical customers, and have over 70 employees and sales revenues of nearly $10 million dollars.”

Today the shop has an eclectic mix of CNC machine tools from Haas Automation and Okuma —although Albright pointed out that Haas machines are "Made in America," which resonates with many of Stellar’s customers — and Stellar prides itself on the frequent updates to its production assets. “This approach also lets us replace our equipment on a more regular basis, which in turn keeps us current on technology,” she explained.

The critical equipment includes an Okuma LB-45 lathe able to turn 36-in. diameter parts up to 120 in. long (91 mm x 305 cm), and a Haas VF-11 five-axis machining center with 10 ft. of X-axis travel (305 cm) and a table load capacity 4000 lb. (1814 kg). Stellar’s stable also features several wire EDMs, a dozen or so three-, four-, and five-axis machining centers and mill-turn lathes, and it offers value-added services like non-destructive testing, welding, heat treating, and Teflon coating.

Inconel's Not So Tough

Stellar Precision Components is used to meeting demanding requirements. Among the work orders it has completed have been components for RAM Block II anti-ship missiles; the CCtCap crew transport vehicle, 155-mm Long Range Land Attack Projectile (LRLAP) advanced gun systems; and rocket motor cases for the Atlas Five launch vehicle, among others. However, one of the shop’s most recent projects tested the mettle of machinists and management alike.

Frieze explained that Stellar had just received a purchase order for a handful of Inconel 625 prototypes. The raw material blanks for the job measured 18 in. square x 3 in. thick (457x457x76 mm), and each one weighed nearly 300 lb. (134 kg). The project team was not deterred by the tough material’s poor machinability; Stellar routinely cuts Inconel and other nickel-based superalloys, as well as tungsten, maraging steels, 60 Rc 4340 (300 M), and tool steel.

Nor was tolerance an issue. Frieze pointed to one recent titanium part that called out a 0.005 in. (0.127 mm) profile tolerance over its 12 in. length (304 mm), the equivalent of holding “a couple tenths” in parts that cost over $5,000 each before machining. Meeting the relatively wide-open tolerances on the Inconel part was not a concern.

The problem was one of raw material removal: when finished, the Inconel plates weighed 30 lb. (13.6 kg), 90% lighter than their starting weight. Frieze knew there are not enough hours in the day to remove that much material using conventional carbide tooling, not if Stellar were to meet the deadline. He needed a better solution.

Seminar notes — A few months before, Frieze and several of his coworkers had attended a learning event sponsored by a local National Tooling and Machining Association (NTMA) chapter, hosted at the Kennametal technical center in nearby Latrobe, Penn. There he met product manager Matthieu Guillon, who introduced him to a cutting tool that made Frieze skeptical, at first. “It looked and felt like a plastic toy end mill,” he laughed as he recalled the details.

The tool was Kennametal’s series of four- and six-flute, high-performance full ceramic end mills. Constructed of SiAlON KYS40 grade ceramic and designed specifically for roughing in nickel-based high-temperature alloys, these end mills often out-produce carbide by up to 20 times. Said Guillon, “We recommend a starting speed of 825 SFM up to 3,300 SFM (250 to 1000 m/min), and feed-rates starting at around 0.001 IPT (0.03 mm), depending on the tool diameter and other conditions. Despite the far higher cutting speeds, we have some customers who have reported two to three times greater tool life than carbide.”

Stellar didn’t have any immediate use for the ceramic tools, but after making some quick feed-and-speed calculations, Frieze knew they would be an effective solution given the right application. Several months later, that application arrived with the Inconel plates. He called Guillon to say he might have a good use for those ceramic cutters they had talked about, and wondered how soon he could get some.

Shooting Fire, Everywhere

Frieze remained skeptical, though. He’d tried indexable ceramic cutting tools on both milling and turning jobs in the past, with mediocre results. Now, however, he was willing to try anything if it meant meeting the customer’s deadline. When Guillon arrived a few days later with the ceramic end mills, Frieze followed Kennametal’s feed-and-speed recommendations to the letter, crossed his fingers, and pushed cycle start.

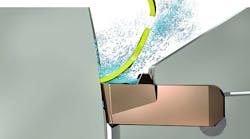

“We weren’t certain what would happen so we started out with a block of test material,” he said. “You don’t use cutting fluid with ceramic, only an air blast, and everyone in the shop was crowded around the machine saying, ‘Wow, look at that!’ There was fire shooting everywhere. It was something we’d never seen before. But within the first hour, we knew it was going to work.

“The tools aren’t inexpensive,” Stellar’s production manager continued. “At one point, Lori had around $20,000 worth of end mills sitting in her office and we were starting to question the investment. But once we calculated in the machine costs and reduced cycle time, we figured it was three to four times more cost-effective to go this route.

“Each end mill gave us one half-hour of cut time,” Frieze detailed, “at which point we replaced it whether it was worn or not. The process was so predictable we were able to run lights-out. It was a drastic savings.”

Zero scrap, and another RFQ — Best of all, Stellar Precision Components delivered the Inconel parts on time with zero scrap, and the customer returned with a request for a second, even larger order. Owner Lori Albright was quite pleased with the outcome. “This type of situation is the nature of our business. We have to react to our customers’ needs and employ the best technology available to do so. That’s one of the reasons why Kennametal is so welcome here. We work together as a team to solve challenges.”

Now Albright is anticipating continued growth for the aerospace machine shop. Having expanded Stellar’s existing operation six times, she is considering whether to invest in an entirely new building, nearby. And, she looks forward to bringing more young people to the machining trade.

“We have apprenticeship programs with several of the area schools, one of which my father used to teach at,” she said. “I find that it’s often our younger people that drive our innovation. It's too easy to keep doing things the old way and not to invest in tooling and equipment, or pursue new technology. The days of high volume, round-the-clock fender clip manufacturing are gone, and it’s only by continually improving their manufacturing processes that companies can succeed and grow.”