Breakthrough Facemill Doubles Aluminum Machining Rates

Judging by field experience under both high-feed and high-depth conditions, a new Ingersoll facemill can double machining rates versus the nearest PCD (polycrystalline diamond) competitor, and extend tool life, and leave chatter-free finishes at 16,000 RPM spindle speeds and above.

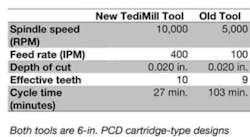

• Under high feed conditions using light cuts, Continental Motors Inc., in Mobile, Ala., is face-milling aluminum castings for aircraft engines at 10,000 RPM, 400 IPM and 0.020 in. DOC, with a sixth Ingersoll TediMill PCD cartridge mill. That result doubles the rate that Continental Motors achieve while using the previous PCD cutter. Edge life improved, too.

• Under heavier conditions, including deeper interrupted cuts, Ward Production Engineering in Fort Wayne, Ind., also doubled its rate of throughput for aluminum castings, using the same PCD TediMill. Parameters with a sixth mill are now 10,000 RPM versus 5,000 previously; 420 IPM versus 140; and 0.200 in. DOC versus 0.060 in. Despite the heavier cuts, edge life improved 50%.

There are three design details promoting this higher level of performance by the Ingersoll TediMill — details not found in any other aluminum facemill, whether PCD or ICI: extremely rigid cartridge seating; positive rake presentation; and through-tool coolant direct to the cutting zone. The tool comes with a level of dynamic balance that qualifies for 16,000 SFM cutting speeds right out of the box, leading to the chatter-free 3.2 µ finishes as well. In fact, the TediMill tools have run at 54,000 RPM vibration-and chatter-free in independent tests on the fastest spindle in the world. So, by ISO standards that particular cutter can be rated to run as high as 27,000 RPM in production environments.

TediMills are the only cutting tools offered as standards from Ingersoll’s sister company in the IMC Group, Italian Technical Diamond Company (IT.TE.DI). Heretofore the company has specialized in custom high-precision PCD and CBN boring tools. After convincing successes as “specials” with global automakers, Ingersoll brought the TediMill line to the U.S. market in 2011, first as a special offering and now as a standard product.

Continental Motors' Case

Continental’s retooling began during a regular plant walk-through with Ingersoll’s Bruce Burroughs, to resolve a problem with overheating. On larger crankcases, machining heated the workpieces so much that the operation had to be stopped midway through each part for reclamping, to relieve machining stresses and eliminate part distortion. The tool in use was a mainstream 6-in. PCD, zero-rake cartridge cutter.

Burroughs suggested trying the new TediMill for cooler running because of its free-cutting positive-rake geometry and cutting-zone coolant delivery.

Trials were conducted on Continental’s Toyoda FH630SX horizontal CNC, both to validate the new tool and to establish machining parameters for operational use. Here are the highlights:

He ramped up to the trial parameters very shortly, and the operation has run without incident ever since then. Removal rates for roughing are up by 4-to-1 over the previous ICI cutter; for finishing, the gain is 2-to-1 over the previous PCD cutter. Flatness and finish are improved as well. Stoppages and reclampings are a thing of the past. As a result, Continental also has retooled roughing operations on other parts with a 4-in. TediMill taking 0.090-in. depths of cut, and it reports a doubling of throughput versus an ICI tool.

Based on experience to-date, Continental has standardized the TediMill for its machines, with the requisite spindle speed and plumbing. “TediMills are not cheap, so there’s no sense putting them on machines that hold them back,” Brown said.

Machinists at Ward Production Engineering switched to the TediMill for the best of reasons: a high-volume, machined aluminum casting program that required an 8% capacity increase after a contract renewal. In fact, the company was considering a $500,000 capital outlay to meet it.

Operating two Mazak Cadet horizontal CNC mills, Ward was running flat out at 5,000 RPM, 140 IPM, 0.060 in. DOC, using the previous cutter. Attempts to speed up the process led to broken inserts, ruined a $1,900 cutter body, or stalled the spindle. Severe interrupted cuts just made things worse.

Ward Adds Capacity, Not Expense

Ward foreman Gary Short learned of the new cutter at an Ingersoll tooling seminar in Rockford, Ill. That program included a demo of the TediMill with brazed PCD inserts completing parts very much like those processed at Ward, but twice as fast as the nearest PCD competitor. And, it left a chatter-free finish while running at 16,000 RPM.

When IT.TE.DI. NA’s Craig Bastian visited the Ward plant to conduct a tooling trial with Ingersoll’s Jim Plummer, it was obvious that the 10,000 RPM spindles on Ward’s Mazaks wouldn’t make the most of the TediMills’ high-speed machining capabilities. So he recommended doubling the speed to 10,000 RPM, tripling the feed rate to 420 IPM, and more than tripling the depth to 0.200 in.

“The TediMill is actually a multi-purpose tool,” he explained. “Yes it is balanced for faster spindles and features high-feed geometry, but it’s also strong enough to dig into a 0.200-in. cut safely. Let’s not forget, it takes a very strong cutter and very rigid insert cartridges to mill at 57,000 RPM, chatter-free and without flying apart. And, a Mazak Cadet is a beefy machine built for machining steel — so it certainly could handle aluminum.”

Gary Short wasn’t so sure of that, so they backed off at first. Even at reduced machining rates, the $20,000 package of TediMills sped things up enough to project the capacity increase without a $500,000 capital outlay. Arrangements were made with the local distributor to ensure a steady supply of inserts and other replacement parts. This was a high-volume part running 24/5 all year long. That done, the ROI was an easy sell to the managers at Ward Production Engineering: buy a couple of $2,000, 6-in. Tedi face mills and add a Saturday shift, … and pick up the 8% capacity increase that the customer’s order necessitated.

After some confidence-building experience, Ward has raised machining rates to Bastian’s original recommendations. All facemilling on the manifold is completed in 58 seconds now, down from 1:51 with the previous, positive-rake cutter PCD or ICI cutters. Ward had tried both.

“Even at these rates, I’m sure there is headroom to go even faster,” Gary Short observed. “We know the tool will take it because we’ve accidently taken a 14-mm cut (more than half an inch) and didn’t harm the tool at all. The worst that ever happened was one fractured insert.”

Short estimated 50% longer insert life versus the previous PCD tool.

Since the initial switch, Ward has tooled five more machines with TediMills, essentially standardizing on the tool for all aluminum facemilling. The 4-in. cutters have titanium bodies, the 6-in. cutters are aluminum. The average margin of improvement on all jobs has been consistent: about 2-to-1 in cycle time, and 50% in edge life.

“To me, the biggest difference over other PCD facemills is the much more rigid insert cartridge seating, which keeps everything stable at these higher machining rates,” Gary Short said.

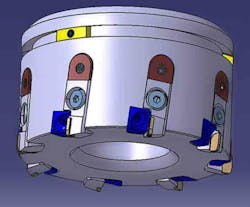

Unlike all other PCD cartridge mills, the Ingersoll TediMill features absolutely rigid cartridge seating, positive-rake presentation, and coolant delivery directly to the cutting edge (see Figure 1.) The cartridge is clamped to stop movement in one direction and wedged to stop movement in the other. The cartridge has smooth, precise, simple axial adjustment to 2 microns, to optimize balance in spindles running at 20,000 or above. Insert corner radii are replaced by small, 45-degree chamfers to reduce axial cutting forces. The cutters also are dynamically balanced to meet 16,000 SFM ratings right out of the box, and have withstood 54,000 RPM in independent tests.

About the Author

Doc Ardrey

Principal

Doc Ardrey is a veteran writer on developments and trends in the design of cutting tool products.