Last year Siemens PLM acquired UGS Corporation, the makers of Unigraphics CAD/CAM software, and promptly renamed the software NX.

When talking to long-time users of the software, the name Unigraphics comes up more frequently than NX, but by whatever name the software is called, it is still one of the top CAD/ CAM packages no matter how such things are measured.

According to CIMdata’s annual survey of CAM software developers, NX is rated as second behind Mastercam in total number of seats, both educational and industrial.

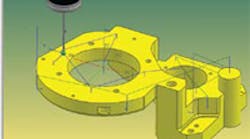

But NX is much more than just a CAM package. It is a fully integrated Computer Aided Design, Computer Aided Manufacturing and Computer Aided Engineering software.

Now that it has been acquired by Siemens PLM it is rapidly becoming integrated with Siemens’ Product Lifecycle Management software with the goal of providing all of the software needed by the engineering department, shop floor and front office of a manufacturer.

Several years before Siemens acquired UGS and renamed Unigraphics to NX, UGS acquired Technomatix, a maker of Coordinate Measuring Machine (CMM) programming software. That software was, and still is used in packages other than Unigraphics/NX such as Catia and Pro/E. It was originally used as a plugin by Unigraphics but has been integrated directly into NX so that the CMM programming function has the same look and feel of the CAD and CAM modules.

The CAM functions of NX have already been enhanced to provide for on-machine part inspection that functions much the same as any machining operation. The same part model file is used for both CNC and CMM programming and can be used to drive a CMM probe as you would a cutting tool. Instead of calling out a particular cutting tool, the programmer can call out a probe for inspection. Because NX uses a proprietary file format, it has incorporated the recoding and use of Geometric Dimensioning and Tolerancing (GDT) data so that GDT data can be attached to the 3D model and can be transmitted and used electronically by other modules. Work currently is underway to use the GDT data automatically in inspection functions.

NX can import 2D and 3D part models in all of the current formats. It then converts it to NX format for use with the NX modules and can export models in most formats needed by other users.

NX also can be used to design tooling and fixtures. It has a strong market share in the tool and die industry and provides optional modules specifically tailored to customer needs in those areas. That includes productivity tools for designing injection molds and other similar products.

When Siemens acquired the Unigraphics software, it also acquired most of the people who have worked for years developing and supporting Unigraphics.

Those employees bring a wealth of knowledge about the core software that gives them a solid base for integrating NX with Siemens’ PLM software to provide the fully integrated and comprehensive software solutions they are working to provide.

Like all software packages, NX comes in modules, and customers can buy only what they need, knowing that if their needs change, they can acquire other modules to meet their increased needs, and that the new modules will be fully integrated and compatible with the modules they purchased originally.

NX has a reputation for being high-end in cost, but compared to the cost of buying individual products to match NX’s capabilities, its cost becomes competitive and offers fully-integrated functionality from a single supplier. As Siemens’ PLM software becomes more integrated with NX, it opens the door to a true single-supplier solution to all of a manufacturer’s software needs.

Even though NX has strong penetration into the tool and die industry, the software is in use across a wide range of industries and shop sizes.

Smaller shops that are concerned about NX’s reputation for being costly could compare its cost to the total of the other software products they are using currently or planning to buy before deciding the software really is too expensive. In a world filled with complaints about the incompatibility of various software products, NX offers a safe harbor of a comprehensive, stable, fullfeatured software solution from a single vendor.