A machine shop in Hutchinson, Minn., supplies components for process control system developers, medical equipment producers, and aerospace manufacturers, among others. Over the past few years, RD Machine Inc. has purchased a number of 4- and 5-axis CNC machining centers with the goal of increasing productivity by reducing the number of setups required to produce complex parts.

“Our previous CNC programming software worked well in 2- and 3-axis machining, but we discovered that it was not the right tool for 4- and 5-axis machining centers and mill-turn lathes,” explained RD Machine president Jeff Laway.

Based on the recommendation of one CNC machine builder, RD Machine switched to ESPRIT CNC programming software developed by DP Technology Corp., which offers numerous processing capabilities installed especially for 4- and 5-axis machining, as well as mill-turn machines.

“ESPRIT is designed specifically for today’s latest machine tools, and provides a wide range of features that help us get the most out of these machines while simplifying the programming task,” Laway said. “The end result is that we can now take full advantage of the power of newer machine tools while reducing programming time by about 25%.”

RD Machine distinguishes itself among other shops by investing in the latest available technology, so its customers have the highest standards of quality available, competitive pricing, and fast delivery times.

For example, recently the shop purchased a Makino PS95 vertical machining center with simultaneous 4-axis machining plus one additional positioning axis. The critical advantage of the additional axes is the ability to move the part so that the tool can access it from nearly any angle, to machine surfaces at compound angles, drill holes at angles, access hidden surfaces, etc.

So, a complex part that might formerly have needed up to 15 setups and many custom fixtures now can often be machined with only one or two setups, with no need for custom fixtures. This substantially reduces the amount of time required to machine the part, which in turn enables the company to offer more competitive pricing and faster delivery times.

Quality is improved also because reducing the number of setups makes it possible to control the relationships between different features more closely than was possible in the past. RD Machine’s mill-turn machines achieve similar advantages by completely machining parts that would normally require operations on both a turning center and a machining center.

Programming challenges

When RD Machine began using 4- and 5-axis and mill-turn machines, the company began to recognize the limitations of its former CNC software. “The programming complexity is much greater with the newer generation of machines,” Laway elaborated. “We found that we were unable to access many of the capabilities of these machines through our previous software.

“In many cases,” he continued, “we had to write manual code in an effort to take full advantage of these machines. This substantially increased the amount of time required for programming and created the potential for errors, which took additional time to resolve. In a number of cases, we also had difficulty getting the code produced by our old software to run on the newer machines.”

Laway contacted the manufacturers of several of the newer machines and received a recommendation for ESPRIT. The software is specifically developed to meet the challenges of programming for 2- 5-axis milling, 2- to 22-axis turning, 2- 5-axis wire EDM, multitasking mill-turn machining and B-axis machine tools, and high-speed, 3- and 5-axis machining. For example, it offers a range of milling strategies designed especially for 5-axis milling, such as composite milling, ruled swarf miling, surface swarf milling, contour milling, and impeller milling.

RD Machine invested in one seat of ESPRIT, and later a second seat as the advantages of the new software became clear. “ESPRIT provides an excellent platform for programming 4- and 5-axis and mill-turn machines,” Laway concluded. “It can import a solid model from nearly every CAD program, and nearly always gets the geometry right the first time.

“Feature recognition saves a substantial amount of time by quickly and accurately adding the intelligence back to the model that is inevitably lost when the geometry leaves the proprietary environment of the CAD system,” he commented.”

ESPRIT offers machine programmers a range of milling strategies that are specifically designed to take advantage of the capabilities of 4- and 5-axis systems, as well as many others designed for 3-axis machines.

“ESPRIT’s simulation capabilities help to ensure that, in spite of the complexities of 5-axis machining, our programs work right the first time we try them,” according to Laway, “and also does a much better job in supporting the capabilities of advanced machines with their posts. We almost never have to write manual code anymore.”

Medical examples

As an example of the programming improvements that RD Machine has achieved with ESPRIT, Laway cited a class of medical device parts the company programs on a regular basis. In the past, these parts required considerable volumes of manual code to be programmed in order access the machine’s fourth and fifth axes. Problems were often experienced with this code, which required extra time to resolve.

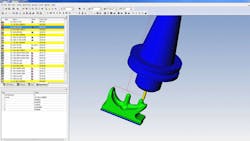

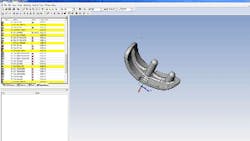

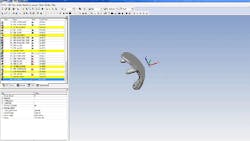

The programming process was simplified significantly with availability ESPRIT. Laway began programming the latest part by importing the customer’s solid model, which contained the geometrical definition of the part. Then, he used ESPRIT’s automatic feature-recognition capability to restore the intelligence to the geometry by organizing it into features such as holes, bosses, pockets, chamfers, fillets, etc. He checked over the features recognized by the software and made a few changes.

The next step was to define the machining operations. The ESPRIT KnowledgeBase™ helps a programmer or operator determine the best method to machine a given part or feature by automatically selecting the most appropriate machining cycles, cutting tools and machining parameters based upon best practices saved by the company.

Laway used ESPRIT’s 5-axis composite milling function to define the machining patterns and tool orientation strategies independently, to be used when creating the toolpath. This function includes 20 different machining strategies so it can handle nearly any geometry. Laway also used the 5-axis contour milling strategy, in which the tool follows a curve while keeping its axis perpendicular to the part surface.

Realistic simulation, visualization

For each toolpath, Laway selected a tool and defined its diameter, length, tool holder and speeds and feeds. After the toolpath was generated, he used ESPRIT’s simulation functionality to visualize the cutting process. The realistic simulation and visualization generated by ESPRIT rendered the complete cutting process with lifelike realism, including all toolpath, inclined or indexed, from 2 to 5-axis. The simulation is not limited to a simple graphical effect, but provides the advance detection of any unreachable axis position, or collision of the machine’s moving parts, the tool and its holder, and the part being produced. Laway also viewed a presentation of the part that would be produced by the program and compared the as-machined workpiece to the original design. He spotted a few areas where improvements were possible and made tweaks to the program.

Just like the majority of programs developed by RD Machine, the resulting program worked perfectly the first time it was run on the Makino PS95 5-axis machine. Laway estimated that the time required to program the part was about 25% less than what was required previously to produce similar parts.

He also said that the machining cycles designed especially for 5-axis machining provide significant reductions in machining time on many parts. “By using ESPRIT to generate CNC programs for our 4- and 5-axis and mill-turn machines, we have substantially increased our capabilities to deliver high-quality parts to our customers at a competitive price with fast delivery times,” Laway summarized.

“Our 5-axis machines are inherently faster because of their ability to produce parts with fewer setups, but ESPRIT generates additional productivity gains with its strategies designed especially for 5-axis milling and ability to support the full functionality of these machines,” he concluded. “Finally, the excellent technical support provided by ESPRIT makes it easy for us to take full advantage of the software’s capabilities.”

About the Author

Robert Brooks

Content Director

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries.