At the upcoming SolidWorks World 2011, a three-day conference and trade show for users of the 3D CAD and CAM software program, Roland DGA and MecSoft Corp. will introduce a new design-to-part workflow for multiple applications, such as functional and snap-fit prototypes, nonferrous metal molds, and biomedical components.

Roland designs machines for cutting, engraving, and scanning/milling machines, among other products used by graphic design and modeling groups. MecSoft develops CAM software, including the VisualMILL™, VisualMILL for SolidWorks®, and RhinoCAM™ products used in rapid manufacturing and moldmaking, and industries like aerospace, automotive, woodworking, education, and tool-and-diemaking.

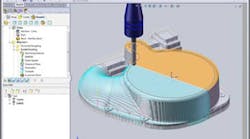

The workflow combines the VisualMILL for SolidWorks CAM with Roland MDX milling machines for a manufacturing system to produce parts and prototypes in various materials, including aluminum, ABS, Acetal, Nylon, acrylic, polycarbonate, wood, plaster and polystyrene.

“VisualMILL for SolidWorks is seamlessly integrated with our MDX series machines, making it easy for designers and engineers to go from SolidWorks to finished prototype,” explains Pedro Gonzalez, product manager for Roland. “The combined solution delivers smooth surface finishes, high repeat accuracies and tight tolerances to exact specifications.”

The Roland MDX line of 3D milling machines are supplied as complete systems, including entry-level CAM software for rapid prototyping and manufacturing applications. By adding VisualMILL for SolidWorks, manufacturers can implement more machining strategies, and thereby higher throughput.