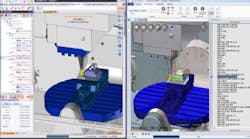

Machine tool operators’ need for faster and simpler programming is driving software developers’ strategies, and promoting more innovative process technologies. Missler Software and Spring Technologies reported a final agreement between them to integrate the latter’s G-code simulation software, NCSimul Machine, as an option which can be used directly within TopSolid’Cam. The new package — TopSolid’NCSimul — will be available this year within the new release of TopSolid’Cam 7.8.

The deep-level integration between standard CAM features and high-end machining simulation is part of the two companies’ strategies, but it is also an example of increasingly advanced and complete workshop solutions that are being developed in machine programming.

Spring Technologies’ NCSimul Solutions platform simulates the complete machining process in real time, including cutting and tool libraries, post-processing, NC simulation, technical content publishing and DNC monitoring.

Missler Software is a French developer whose TopSolid CAD/CAM/ERP software is concentrated in mechanical manufacturing, toolmaking, wood and sheet metal processing industries.

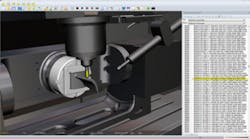

The initial objective of the two firms’ agreement is to ensure a coherence and workflow between TopSolid and NCSimul Machine. As a CAM software, TopSolid’Cam determines toolpaths that are close to the part, taking account of machine kinematics and material constraints. As a CNC simulation software, NCSimul Machine’s purpose is to conduct independent checking and toolpath optimization, quickly, and close to the machine and the controller.

The combination of the two will underscore security and assurance throughout the machining process and programming stages for the customer, which is especially important when the parts being produced involved expensive materials or the machining cycle takes many hours. Defining and maintaining accurate toolpaths that optimize materials and manufacturing time is important.

Initial Objective, Long-Term Goal

The collaboration between Missler Software and Spring Technologies is important for Missler Software, according to CEO Christian Arber. “In fact we have many customers in common with Spring Technologies. TopSolid’NCSimul offers important time gains to these customers, which thereby results in a competitive advantage for these companies and future potential clients,” he said.

“The development of the interface and the future integration between the two solutions is an important step in the validation and optimization of the G-code generated by TopSolid’Cam post-processors,” Arber continued. “The part and machine environment simulation already provided by TopSolid’Cam together with the advanced G-code simulation provided by TopSolid’NCSimul will no doubt help reduce potential collisions.”

Gilles Battier, CEO of Spring Technologies, predicted that the commitment between the two companies would “progressively generate a very complete and reliable solution covering all workshop needs.

“In the 2014 version we ensure that a maximum level of integration and interoperability is maintained for the customer. Going forward NCSimul Machine will be completely transparent for the user within TopSolid’Cam, and we are confident that we will be able to offer many more integrated solutions to our respective customers.”

In the longer term, the two companies stated they plan a deeper integration of Spring Technologies solutions within the TopSolid’Cam for Cutting Tool Management and Optimization. Missler Software and Spring Technologies aim to secure high end companies in their machining processes, with independent control. TopSolid’NCSimul is positioned as an affordable solution that is well positioned both in terms of technology and pricing.