A new release for AlphaCAM 2016 – a design-focused CAD/CAM platform from the VISI software family — brings several new features and some enhancements that the developers noted would improve automation processes, machining performance, and feature extractions for programmers. AlphaCAM 2016 R2 also contains various “general improvements,” and new user interface commands for to speed and simplify work processes.

For example, AlphaCAM Clipboard makes it possible to cut, copy, and past design elements in the Drawing Area between different versions of the software open on the same PC. Another option has been added for pre-drilled holes as the entry type on waveform roughing operations.

A new method allows the programmer to select faces in order to “extract” part contours in work planes. “This improved ‘feature extraction’ on user-selected multiple angled faces is a real time-saver,” said EMEA sales manager Michael Pettit. “Feature Extraction also has been enhanced using an updated algorithm for finding contours.”

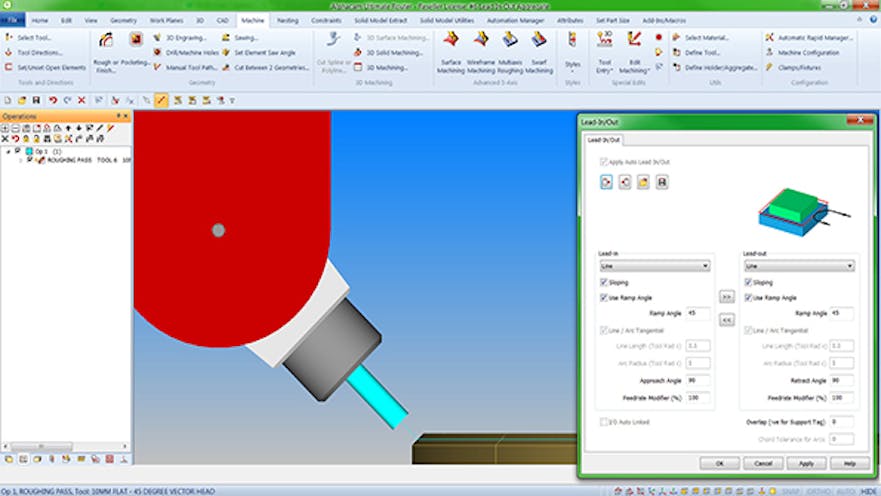

Some machining dialogs in AlphaCAM 2016 R2 have a new tab containing specific options for either 2D or 3D lead-in and lead-out paths, and there is an option to save and open user-configured lead settings, in addition to the defaults. “It’s now possible to copy all settings both ways between the lead-in and lead-out sections,” according to Pettit.

A new option achieves tool angle direction entry into a part when machining features, such as grooves and slots.

A number of updates to AlphaCAM’s Automation Manager include changes to Job Settings, Machining Order, Layer Mapping, and added support for nesting small parts into defined zones:

• Job Settings: When adding new files to a job, Automation Manager sets parameters for Layer Mapping Setup, Material and Machining Order to ‘From Job’ by default. They can be overwritten if necessary, for a particular file.

• Machining order: The new Machining Order tab replaces the former Tool Ordering tab, defining the order of machining operations. The order lists are associated with layer mapping setups and machining styles...and multiple machining lists can be configured.

• Layer mapping: A New Drawing Layer command button has been added to the ribbon bar in the Layer Mapping Setup tab enabling users to create layers manually, and add layer names without having to import them from a drawing.

• DXF/DWG Import Support for Z levels from parallel planes: The Layer Mapping Setup tab has a new import option for DXF, DWG and AlphaCAM drawings and functions, meaning that parts which would have had work planes are simplified to Auto Z, and can be nested correctly.

• More support for nesting small parts into defined zones: After drawing a sheet and adding it to the sheet database, parts can be defined as small parts for nesting zones by using the new Small Nested Part option in the Processing tab.

Among many changes to how AlphaCAM 2016 R2 handles geometry, new ribbon bar command buttons have been added to the Parametric Sketcher dialog, enabling users to associate an image with Parametric Sketches (.aeps) and Variables (.aepsvars). The associated images will be displayed in the Project Manager’s Insert page.

Processing time is reduced when creating a simplified version of a detailed model where roughing paths do not require a high level of detail. Using the 3D / STL Utilities / Simplify command, the number of facets in a model can be reduced as a percentage of facets in the original.